SAFETY FEATURES AND EQUIPMENT 7-9

PA1633 X3-45 Commuter Operator’s Manual

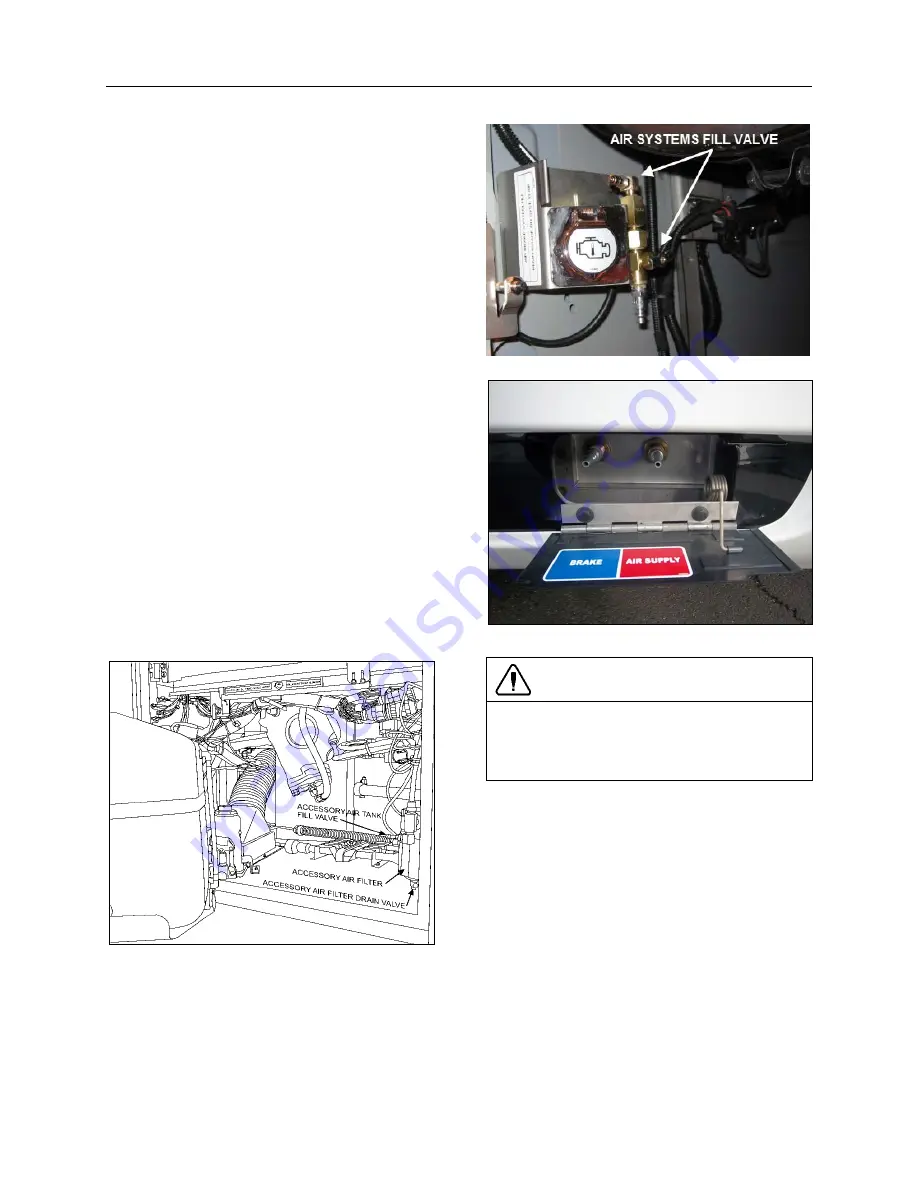

EMERGENCY AIR-FILL VALVES AND

QUICK CONNECTOR FITTINGS

The vehicle is equipped with three (3) air system

emergency air-fill valves to supplement the air

system when air pressure is low and the engine

cannot be operated.

Air system emergency valves are fitted with

either standard tire valve stem or quick

connector fitting. The air systems can be filled

using any standard external air supply line.

Air-fill valves are as follows:

1- One air-fill valve fitted with standard tire valve

stem located in the engine compartment

supplies air for all systems through the air dryer

(brakes, suspension and accessories).

2- One air-fill valve fitted with standard tire valve

stem located in the front service compartment

supplies air for accessories only.

3- One quick connect air-fill fitting identified

AIR

SUPPLY

located behind the flip down access

door on the front bumper supplies air from a tow

truck for all systems through the air dryer

(brakes, suspension and accessories).

One quick connector fitting identified

BRAKE

located behind the flip down access door on the

front bumper supplies air for operation of the

vehicle service brake from the tow truck.

AIR-FILL VALVE IN FRONT SERVICE COMPARTMENT

12210

AIR-FILL VALVE IN ENGINE COMPARTMENT

12211_1

QUICK CONNECTOR FITTINGS ON FRONT BUMPER

CAUTION

Air filled through the three emergency air-fill

valves will pass through the standard air

filtering-drying system. Do not exceed 144 psi

(993 kPa).

EMERGENCY AND PARKING

BRAKES

During normal operation, if air pressure in all

brake circuits drops below 60 psi, spring-loaded

emergency brake will be immediately applied at

full capacity to the drive axle wheels to stop the

vehicle.

Spring-loaded parking brake is applied by pulling

up the control valve knob located on the L.H.

lateral console.

Parking brake is not designed to be used as a

service brake. For normal driving conditions, the

control valve knob must remain in the down

position.

Summary of Contents for X3-45 COMMUTER 2018

Page 1: ...OPERATOR S MANUAL X3 45 COMMUTER COACH...

Page 2: ......

Page 3: ...COACH MANUFACTURER X3 45 COMMUTER OPERATING MANUAL March 2018...

Page 4: ...PA1633 MARCH 2018 Featuring REVISION DESCRIPTION DATE FIRST RELEASE 03 2018...

Page 8: ......

Page 12: ......

Page 70: ...4 36 CONTROLS AND INSTRUMENTS PA1633 X3 45 Commuter Operator s Manual...

Page 108: ...5 38 OTHER FEATURES PA1633 X3 45 Commuter Operator s Manual...

Page 116: ...6 8 STARTING AND STOPPING PROCEDURES PA1633 X3 45 Commuter Operator s Manual...

Page 120: ...7 4 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual KIDDE IMAGES...

Page 128: ...7 12 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual...

Page 148: ...8 20 CARE AND MAINTENANCE PA1633 X3 45 Commuter Operator s Manual...

Page 150: ...9 2 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual OVERALL DIMENSIONS...

Page 158: ...9 10 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual...

Page 160: ......

Page 164: ......