TECHNICAL INFORMATION 9-7

PA1633 X3-45 Commuter Operator’s Manual

DRIVE AXLE ZF A-132

Minimum

value

Nominal

value

Maximum

value

Thrust

angle

±0.11°

Total toe

0.15°

toe-in

0°

0.15°

toe-out

TAG AXLE

Minimum

value

Nominal

value

Maximu

m value

Thrust angle*

(degrees)

-0.02

0

0.02

Total toe

0.08°

toe-in

0°

0.02°

toe-out

(*) Use the drive axle as reference

COOLING SYSTEM

•

Extra capacity, copper fin radiator and

aluminum charge air cooler arranged one

behind the other.

•

3 speed fan clutch engine ECM controlled.

•

Rubber insulated from the body.

•

Expansion tank above radiator and remote

mounted.

•

System pressure 13 psi.

•

185

o

F thermostat.

•

System capacity 24 us gal.

•

Coolant filter.

•

Radiator fan: 38 inches fan belt and drive

shaft driven.

FUEL SYSTEM

Steel fuel tank

Fuel legal capacity (corresponding to 95% of

gross capacity): 180 US gallons (681 liters).

Unusable fuel: 6.3 US gallons (24 liters).

Equipped with:

•

Emco Wheaton fuel filling system.

•

Provided with filling access on the right side

of the coach with safety filler cap.

•

Pressure relief valve.

•

Electric fuel gauge.

•

Low level signal at 26 US gallons/98.4 liters.

•

Primary filter 25 microns (standard).

•

Fuel pro 382 filter as primary filter.

•

Secondary filter 3 to 5 microns.

•

Shut-off valve on fuel supply line.

EXHAUST SYSTEM

One all stainless steel exhaust aftertreatment

system including:

•

Catalylic converter to reduce NOx.

•

FleetGuard assembly made of a DOC (Diesel

Oxidation Catalyst and a DPF (Diesel

Particulate Filter). Noise, vibration and heat

insulated. This assembly is mounted to the

bus structure and is accessible through an

exterior access door.

•

Tail pipe diffuser and rain deviation device.

•

Exhaust pipe with insulation and a flexible

section.

•

Exhaust to rear left hand top of rear cap.

•

Diesel exhaust fluid (DEF) tank (15.9 gal.)

and injection system.

HEATING AND AIR CONDITIONING

The large capacity A/C provides adequate

capacity of conditioned and filtered air for all

climatic conditions. Fresh air is drawn into the

system from the left (driver’s) side of the vehicle.

Return air is taken from the middle of the

vehicle. The driver’s heater and defogger are

controlled separately from the central unit. An

air mixture selector enables air to be drawn into

the system from outside the vehicle or

recirculated.

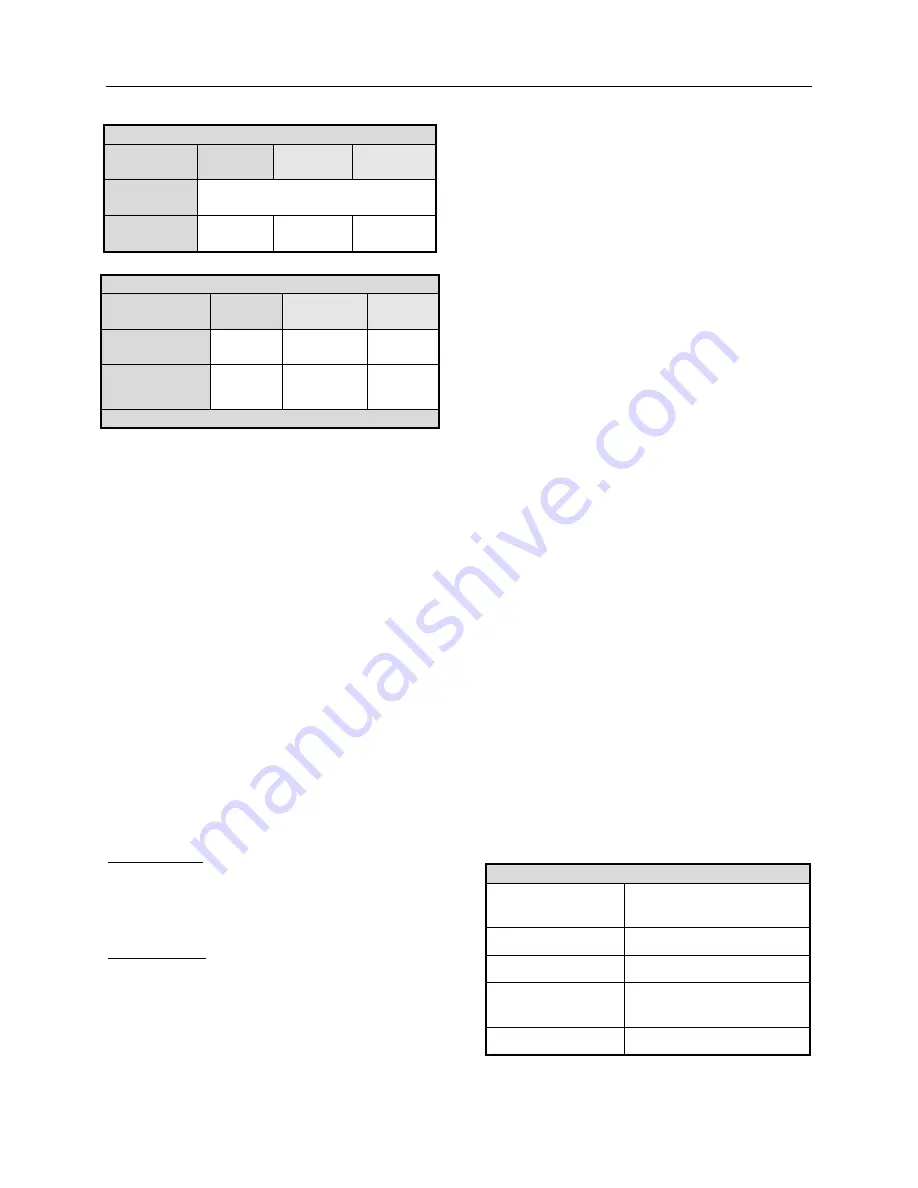

CENTRAL A/C

Air conditioning

capacity

9 tons

Refrigerant type

134A

Heating capacity

152 000 Btu/h

Air flow, overhead

parcel rack evap.

450 cfm (12,7 m

3

/min)

Air flow, main A/C

2 600 cfm (73,6 m

3

/min)

Summary of Contents for X3-45 COMMUTER 2018

Page 1: ...OPERATOR S MANUAL X3 45 COMMUTER COACH...

Page 2: ......

Page 3: ...COACH MANUFACTURER X3 45 COMMUTER OPERATING MANUAL March 2018...

Page 4: ...PA1633 MARCH 2018 Featuring REVISION DESCRIPTION DATE FIRST RELEASE 03 2018...

Page 8: ......

Page 12: ......

Page 70: ...4 36 CONTROLS AND INSTRUMENTS PA1633 X3 45 Commuter Operator s Manual...

Page 108: ...5 38 OTHER FEATURES PA1633 X3 45 Commuter Operator s Manual...

Page 116: ...6 8 STARTING AND STOPPING PROCEDURES PA1633 X3 45 Commuter Operator s Manual...

Page 120: ...7 4 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual KIDDE IMAGES...

Page 128: ...7 12 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual...

Page 148: ...8 20 CARE AND MAINTENANCE PA1633 X3 45 Commuter Operator s Manual...

Page 150: ...9 2 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual OVERALL DIMENSIONS...

Page 158: ...9 10 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual...

Page 160: ......

Page 164: ......