CARE AND MAINTENANCE 8-7

PA1633 X3-45 Commuter Operator’s Manual

or under the lower HOT RUN line, add just

enough oil to bring up the level to the middle of

the HOT RUN band.

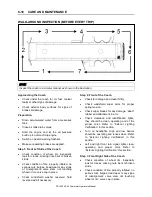

TRANSMISSION FLUID LEVEL DIPSTICK (TYPICAL)

07049

Replace dipstick and tighten the filler tube cap

until the rubber seal is correctly seated.

CAUTION

Do not overfill transmission fluid reservoir.

Severe damage may result.

POWER STEERING FLUID LEVEL

The power steering hydraulic fluid tank is

located in the engine compartment, close to the

engine air filter (refer to “Engine Compartment

Overview” image in COACH EXTERIOR

section).

ENGINE COMPARTMENT

14059

Check fluid level as follows:

1. Stop engine, open engine compartment

doors and place rear start switch to OFF

position;

2. Unscrew and remove the dipstick located on

top of the power steering fluid tank and wipe

with a clean rag;

3. Replace dipstick in tank, then remove to

check fluid level;

4. Add hydraulic fluid until it reaches the FULL

mark on the dipstick;

5. Replace and tighten dipstick;

6. Place engine rear start switch to NORMAL

position. Close engine compartment doors.

DRIVE AXLE WHEEL HUBS

The unitized bearings in the axle drive and the

wheel ends are pre-lubricated for life and there is

no need or facility for re-lubrication. Maintain

differential oil at correct level to ensure adequate

lubrication of carrier.

FRONT AND TAG AXLE WHEEL HUBS

The unitized hub bearings used on the NDS

range of axles, are non-serviceable items.

Bearings are pre-adjusted, lubricated and have

seals fitted as part of the manufacturing process.

The bearings are greased for life and there is no

need or facility for re-lubrication.

COOLANT FLUID LEVEL

The coolant system has two tanks; the surge

tank (A) and the recovery tank (B).

Check the coolant level into the recovery tank

(B) when the engine is cold (room or ambient

temperature).

•

If the coolant level into the recovery tank is

lower than the MIN LINE, use the recovery

tank filler cap to add coolant until reaching

the FULL LINE.

Summary of Contents for X3-45 COMMUTER 2018

Page 1: ...OPERATOR S MANUAL X3 45 COMMUTER COACH...

Page 2: ......

Page 3: ...COACH MANUFACTURER X3 45 COMMUTER OPERATING MANUAL March 2018...

Page 4: ...PA1633 MARCH 2018 Featuring REVISION DESCRIPTION DATE FIRST RELEASE 03 2018...

Page 8: ......

Page 12: ......

Page 70: ...4 36 CONTROLS AND INSTRUMENTS PA1633 X3 45 Commuter Operator s Manual...

Page 108: ...5 38 OTHER FEATURES PA1633 X3 45 Commuter Operator s Manual...

Page 116: ...6 8 STARTING AND STOPPING PROCEDURES PA1633 X3 45 Commuter Operator s Manual...

Page 120: ...7 4 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual KIDDE IMAGES...

Page 128: ...7 12 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual...

Page 148: ...8 20 CARE AND MAINTENANCE PA1633 X3 45 Commuter Operator s Manual...

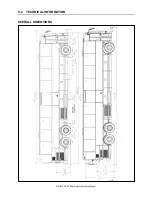

Page 150: ...9 2 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual OVERALL DIMENSIONS...

Page 158: ...9 10 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual...

Page 160: ......

Page 164: ......