9-4 TECHNICAL INFORMATION

PA1633 X3-45 Commuter Operator’s Manual

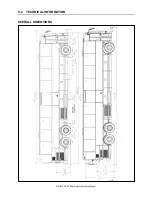

DIMENSIONS, WEIGHTS AND

CAPACITIES

DIMENSIONS AND WEIGHTS

Overall length (incl. bumpers-mirror)

46 ft

Overall width

101 in

Overall height (hatches up)

138 in

Wheelbase (center of front axle

to center of drive axle)

334 ½ in

Floor height from ground

48 ½ in

Ground clearance

11 in

First step height from ground

13 ½ in

Step height (other steps)

7 in

Headroom

80 in

Entrance door opening width

26 in

Front overhang

72 ¼ in

Rear overhang (tag axle down)

90 in

Front track

85.9 in

Drive track

76.7 in

Rear track (Tag axle)

83.6 in

Turning circle radius

(I-Beam Axle)

47 ft 3 in

Curb weight

36,000 lbs

Gross Vehicle Weight Rating

(G.V.W.R.)

48,000 lbs

Front axle Gross Axle Weight Rating

(G.A.W.R.)

16,500 lbs

Drive axle (G.A.W.R.)

22,500 lbs

Tag axle (G.A.W.R.)

14,000 lbs

The Gross Vehicle Weight Rating (G.V.W.R.)

and the Gross Axle Weight Rating (G.A.W.R.)

for front drive and tag axles are listed on a

certification plate located on the L.H. control

panel in driver's section.

CAPACITIES

Volvo D13 Engine oil (Total with

filters)

40 U.S. qrts

Fuel tank (

corresponding to

95% of gross capacity)

180 U.S. gal.

Cooling system

17.4 U.S. gal.

Diesel exhaust fluid (DEF)

16 U.S. gal.

CAPACITIES

Allison Automatic Transmission

(does not include external circuit)

6 U.S. gallons

6.9 U.S. gallons

with retarder

Differential oil (approx)

19 qts

Power steering reservoir

4.0 qts

A/C compressor oil

2.8 qts (2.6L)

Windshield washer reservoir

5.3 U.S. gal.

Refrigerant

30 lb

FUEL TYPE

Diesel engines for 2007 and later model year

vehicles are designed to operate only with

Ultra

Low Sulfur Diesel

(ULSD) fuel, which can

contain no more than 15 ppm sulfur.

CAUTION

ULSD fuel is necessary to avoid fouling the

engine’s Exhaust Aftertreatment System. Use

of fuel other than ULSD will reduce the

efficiency and durability of the engine.

BIODIESEL FUELS

Biodiesel up to a maximum of 20% blend (B20)

may be used and will not affect the

manufacturer’s mechanical warranty as to

engine and emissions system related

components, provided the biofuel used in the

blend conforms to ASTM D6751, B1 to B5

blends conform to ASTM D975, and B6 to B20

blends conform to ASTM D7467. Also, any

engine performance problem related to the use

of biodiesel fuel would not be recognized nor

considered as Volvo or Prevost’s responsibility.

However, Volvo engines are certified to comply

with U.S. EPA and California emissions

standards based upon the use of test fuels with

specifications established by these regulatory

agencies. Alternative fuels, including biodiesel,

that are not substantially similar to the required

test fuels may adversely affect engine emissions

compliance. As a result, Volvo does not warrant

the engine will conform to applicable Federal or

California emissions limits when operated on

biodiesel or other alternative fuels that are not

substantially similar to specified test fuels used

for certification.

Summary of Contents for X3-45 COMMUTER 2018

Page 1: ...OPERATOR S MANUAL X3 45 COMMUTER COACH...

Page 2: ......

Page 3: ...COACH MANUFACTURER X3 45 COMMUTER OPERATING MANUAL March 2018...

Page 4: ...PA1633 MARCH 2018 Featuring REVISION DESCRIPTION DATE FIRST RELEASE 03 2018...

Page 8: ......

Page 12: ......

Page 70: ...4 36 CONTROLS AND INSTRUMENTS PA1633 X3 45 Commuter Operator s Manual...

Page 108: ...5 38 OTHER FEATURES PA1633 X3 45 Commuter Operator s Manual...

Page 116: ...6 8 STARTING AND STOPPING PROCEDURES PA1633 X3 45 Commuter Operator s Manual...

Page 120: ...7 4 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual KIDDE IMAGES...

Page 128: ...7 12 SAFETY FEATURES AND EQUIPMENT PA1633 X3 45 Commuter Operator s Manual...

Page 148: ...8 20 CARE AND MAINTENANCE PA1633 X3 45 Commuter Operator s Manual...

Page 150: ...9 2 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual OVERALL DIMENSIONS...

Page 158: ...9 10 TECHNICAL INFORMATION PA1633 X3 45 Commuter Operator s Manual...

Page 160: ......

Page 164: ......