SECTION 07: TRANSMISSION

12

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

Recommended torque is between 42-50 Lbf-

ft (57-68 Nm).

7. Remove the guide bolt through the access

opening in the flywheel housing. Replace it

with a self-locking screw, finger-tighten then

start the remaining screws; tighten to 17-21

lbf-ft (23-28 Nm). Place a wrench on the

crankshaft pulley attaching screw to turn the

converter to gain access to the threaded

holes.

NOTE

Remove the plug located below starter motor

and install cranking tool (88800014). Crank the

engine to gain access to the threaded holes by

turning the cranking tool using a suitable

adapter.

Reinstall starter motor and connect cables.

Reinstall access plug below starter motor.

8. Remove jack from under transmission.

9. Connect all sensors.

10. Connect the main wiring harness.

11. Connect the air supply line (steel-braided

hose) to the retarder control valve (if

applicable).

12. Connect the two transmission oil cooler

hoses as they were previously.

13. Reinstall clamps and brackets, and replace

locking ties previously removed during

removal procedure.

14. Install propeller shaft and its safety guard.

Refer to Section 09,

"PROPELLER SHAFT".

15. Install transmission dipstick and filler tube.

16. Install cross member under transmission.

17. Install engine splash guards.

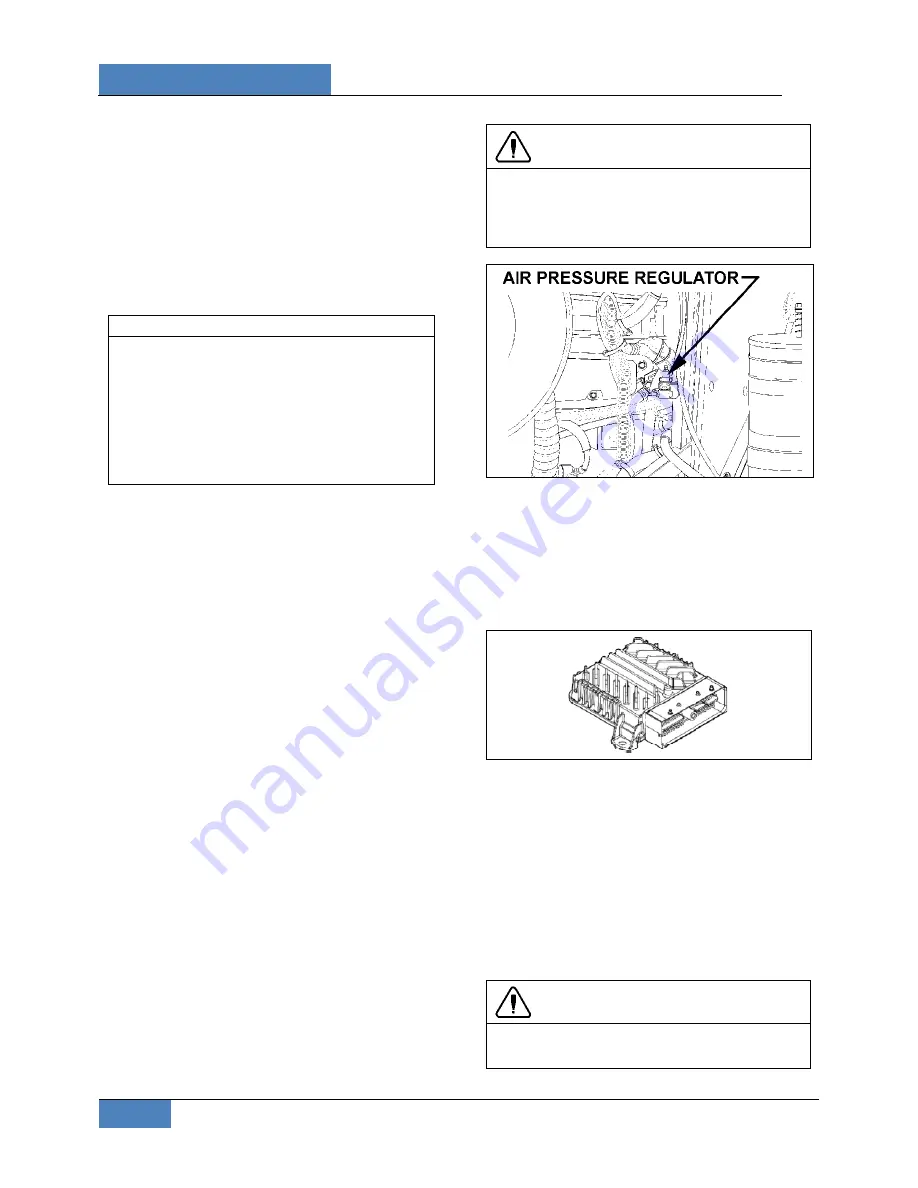

18. Adjust the retarder pressure to 80 ± 3 psi with

the air pressure regulator. For more

information refer to Section 12,

"BRAKE AND

AIR SYSTEM

", under heading

"AIR

PRESSURE REGULATOR".

The air pressure

regulator is located at back of engine

compartment, on R.H. side (Figure 8) or in

the R.H. side rear service compartment.

19. Make sure that the drain plug is in place, and

then remove the transmission dipstick and

pour approximately 24 US quarts (23 L) of

automatic transmission fluid through the filler

tube. Check and adjust oil level.

CAUTION

Do not overfill the transmission. Overfilling can

cause oil aeration (milky appearance) and

overheating. If overfilling occurs, drain oil as

required to bring it to the proper level.

FIGURE 8: AIR PRESSURE REGULATOR (TYPICAL)

07037

6. ALLISON

TRANSMISSION

TROUBLESHOOTING

The Allison transmission has a new Transmission

Control Module (TCM) which involves specific

diagnostic incident codes. The TCM unit is located

in the coach main power compartment.

FIGURE 9: TRANSMISSION CONTROL MODULE

07140

TCM Replacement

The TCM is a non-serviceable electronic device.

When it fails, it must be replaced using the

following procedure:

Open the coach main power compartment in

order to get access to the TCM;

Remove the electrical cable connectors;

Unscrew the TCM unit;

Replace by reversing the procedure.

CAUTION

Place the battery master switch to the ‘’OFF’’

position.