SECTION 09: PROPELLER SHAFT

8

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

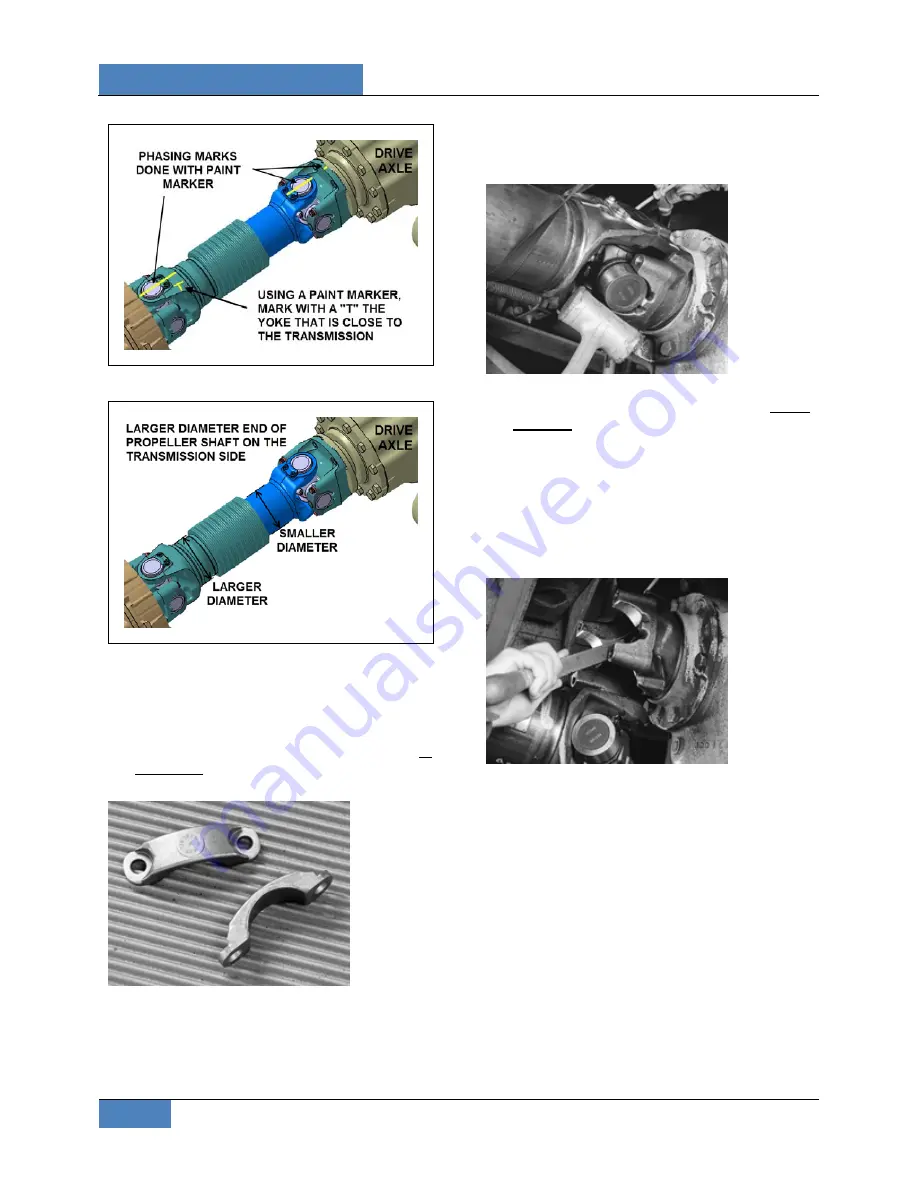

FIGURE 10: PHASING MARKS

FIGURE 11: PROPELLER SHAFT PROPER

ORIENTATION

2. Be sure to ALWAYS use support straps to

prevent the propeller shaft from falling out of

the vehicle.

3. Remove the bearing retainers and bolts at

rear end. Discard bolts, and bearing

retainers.

FIGURE 12: COLD FORMED BEARING RETAINERS

4. It may be necessary to unseat bearing cup

assemblies by tapping on yoke or bearing

cup with a soft-faced hammer. Once the

bearing cup assemblies are free, collapse

the propeller shaft until both bearing

assemblies clear the open end yoke cross

holes. Allow the propeller shaft to rest on

support strap.

FIGURE 13: UNSEATING BEARING CUP ASSEMBLIES

5. Remove bearing retainers and bolts at the

front end.

6. Inspect all end yoke cross hole surfaces and

bolt hole threads for damage. If the bolt hole

threads are damaged, the yoke must be

replaced.

7. Inspect for raised metal or fretting on open

yoke cross holes can be removed with a

fine-toothed file and/or emery cloth.

FIGURE 14: RAISED METAL OR FRETTING ON OPEN

YOKE CROSS HOLES

8. Inspect the end yoke cross holes for

distortion and damage.

4.1.1

Inspect Companion Flange/Flange

Yokes

1. Inspect all flange bolt hole threads or

through holes for damage. If the bolt hole

threads or through holes are damaged, the

flange must be replaced.

2.

Inspect all flange faces for galling or

damage. If damaged, the flange must be

replaced.