SECTION 12: BRAKE AND AIR SYSTEM

18

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

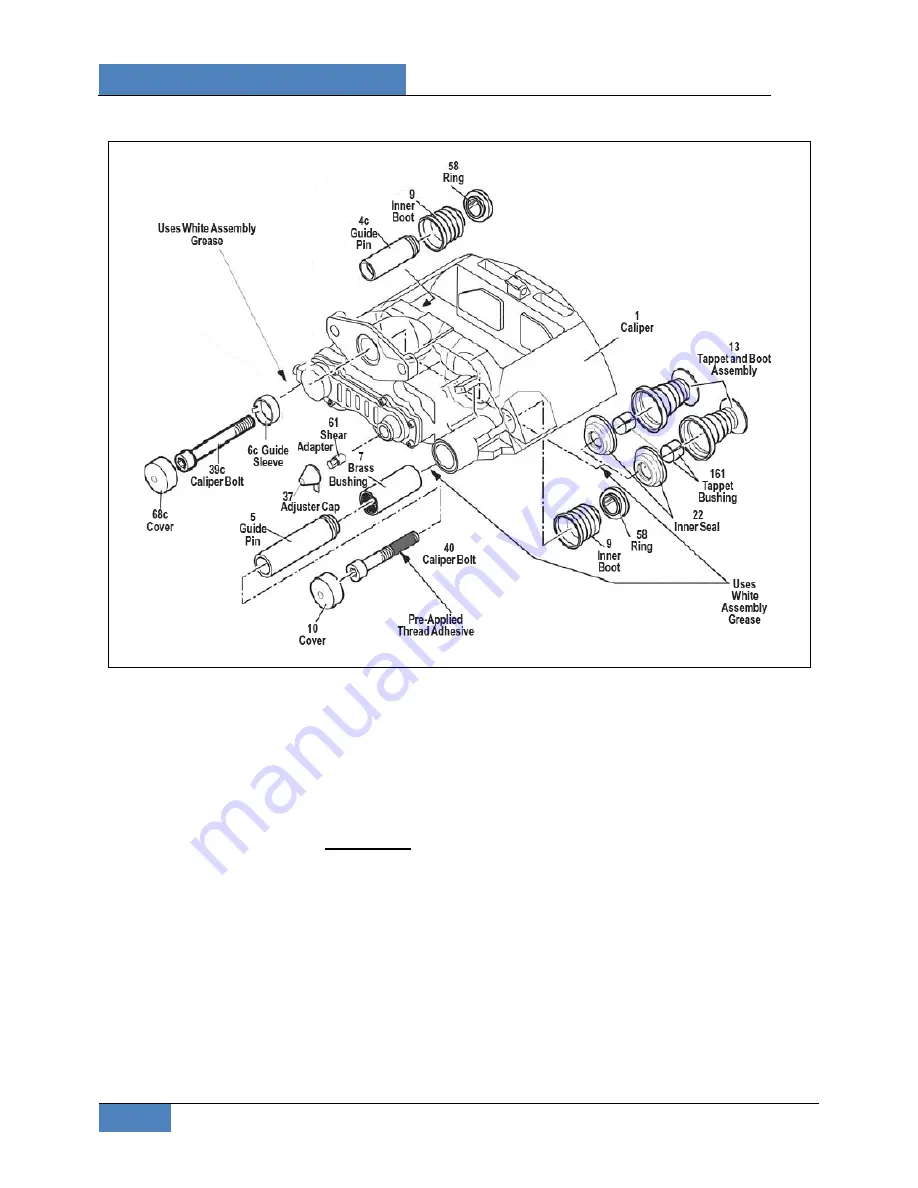

FIGURE 26: BRAKE COMPONENTS

25.2 PAD

REPLACEMENT PROCEDURE

Brake pad replacement procedure has slightly

changed with the introduction of brakes with

improved slack adjusters on our vehicles.

After fitting new pads, adjuster has to be turned

clockwise until pads come in contact with the

disc. Then turn anti-clockwise

three clicks

to

give the correct running clearance.

Please refer to

Knorr-Bremse Y006471

Service Manual, Section 6

for the latest brake

pad replacement procedure.

25.3

CHECKING DISC BRAKE PADS

Brake pads have to be checked on a regular

basis depending on the vehicle operation. The

remaining thickness of the pads should never be

less than 0.079 in (2 mm). When replacing brake

pads, all four pads on an axle have to be

changed at the same time. There is no inner or

outer pad, since all pads are the same.

Once removed, worn pads should be replaced in

their original position. Please refer to Knorr-

Bremse Y006471 Service Manual for further

detail.

25.3.1 Drive Axle – Equipped With L-bracket

Wear Indicator

The condition of the pads can quickly be

checked without removing the wheel by

checking the position of the caliper compared to

the tip of the wear indicator.