SECTION 12: BRAKE AND AIR SYSTEM

20

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

25.3.3 Continuous Wear Sensor.

These vehicles have a potentiometer installed

directly on the brake caliper.

Wear percentage can be consulted via the DID.

Access the « Brake Lining Remaining » MENU

Front axle

wear sensors are connected to

multiplex module

A44

.

Right hand

(curbside) wear sensors for both

rear axles are connected to

A50

Left hand

(road side) wear sensors for both rear

axles are connected to

A51

From the multiplex modules, the signal is sent to

Clever System’s IVN connection

Refer to wiring diagram for details

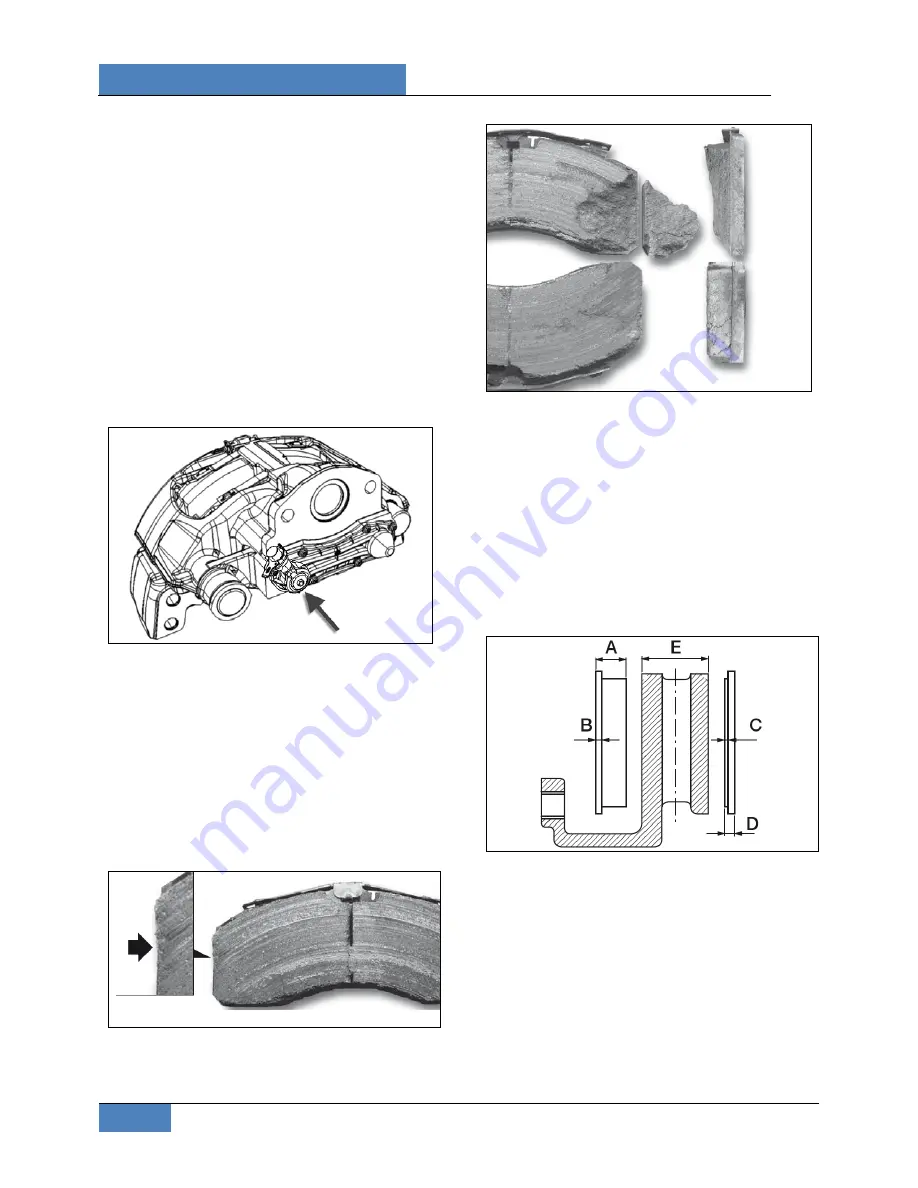

FIGURE 30: POTENTIOMETER

25.4

BRAKE PADS AND DISCS MINIMAL

TOLERANCE LIMITS

25.4.1 Brake Pads

The thickness of the pads must be checked

regularly dependent on the usage of the vehicle.

The pads should be checked corresponding to

any legal requirements that may apply. Even if a

wear indicator is fitted and connected, this must

be at least every 12 months.

FIGURE 31: MINOR BREAKOUTS AT THE EDGES ARE

PERMITTED

FIGURE 32: MAJOR BREAKOUTS ON THE SURFACE OF

THE BRAKE PAD ARE NOT PERMITTED

If the thickness of the friction material at its

thinnest point is less than 0.079 inch or 2 mm

(measurement C), the pads must be replaced.

A=

Overall thickness of new brake pad: 1.18

in (30 mm)

B=

Back plate SN7 type: 0.354 in (9 mm)

C=

Minimal thickness of friction material:

0.079 in (2 mm)

D= Minimum allowed thickness in worn

condition for back plate and friction

material: 0.433 in (11 mm)

FIGURE 33: BRAKE PAD DIMENSIONS

25.4.2 Brake Disc

Measure the thickness of the brake disc at the

thinnest point. Be aware of possible burring at

the edge of the disc.

E= Total thickness of the brake disc

New condition = 1.77 in (45mm)

Worn condition = 1.457 in (37mm) (the disc

must be replaced)

If the disc dimension E

≤

1.535 in (39mm),

it is recommended that the disc should be

renewed when the brake pads are

changed.