SECTION 13: WHEELS, HUBS & TIRES

12

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version

‒

Rev.2 April 2016)

8. The difference between readings is the

amount of mounted end play in bearing unit.

9. The mounted end play figure should not

exceed:

0.050 mm (0.002”)

for a new bearing,

0.20 mm (0.008”)

for a bearing which

has been in service.

NOTE

If original bearing unit is re-fitted, and end-float

is measured at 1 mm, with hub not fully

tightened to correct torque 600±25 lbf-ft, then

the retaining clip within the unit is damaged

and a new unit must be fitted.

8.2 FRONT AXLE HUB BEARING REMOVAL

For detailed information on front axle wheel hub

bearing removal, refer to the following manual

included on your vehicle Technical Publications

CD in PDF format:

Dana Parts & Service Instructions S84U

Steer Axle HUB BEARING REWORK_ Manual

NO 1963 A+B iss A.

See OVERHAUL PROCEDURES, HUB END

DISASSEMBLY, pages No. B3, B4, B5 & B6.

8.3 FRONT AXLE HUB BEARING

INSTALLATION

You can refer to the following manual included

on your vehicle Technical Publications CD in

PDF format:

Dana Parts & Service Instructions S84U

Steer Axle HUB BEARING REWORK_ Manual

NO 1963 A+B iss A.

See OVERHAUL PROCEDURES, HUB END

REASSEMBLY, pages No. B23 up to B30.

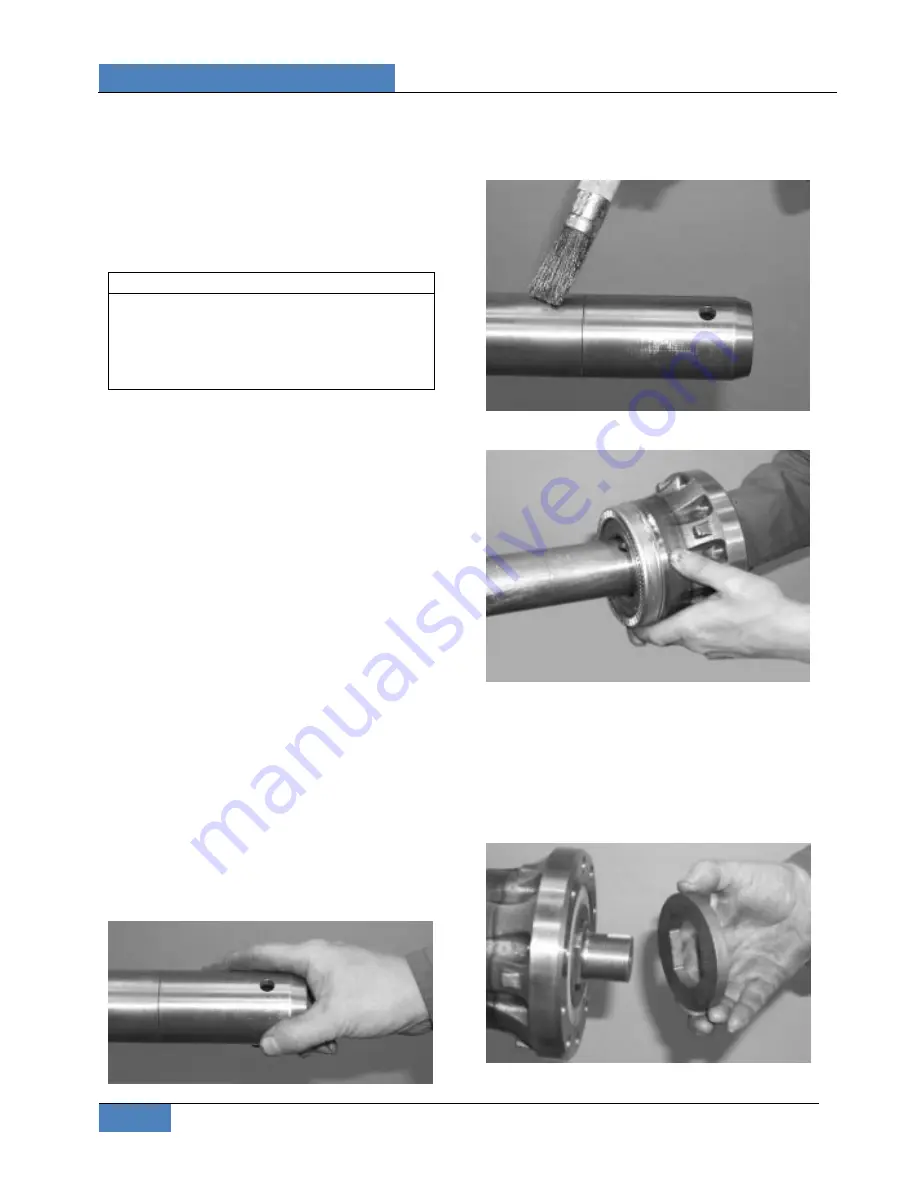

1. Clean spindle using EFX degreaser (Prevost

#685313).

2. Screw insertion tool onto spindle (FIGURE

17).

FIGURE 17: INSERTION TOOL

3. Apply a thin layer of lubricant on spindle

where bearing will be located, use Gleitmo

805 grease (Prevost #685274).

FIGURE 18: APPLY GLEITMO 805 GREASE

4.

Slide unitized hub bearing over spindle.

FIGURE 19: SLIDE UNITIZED HUB BEARING OVER

SPINDLE

5.

Clean thrust washer both sides and hub nut

using EFX degreaser.

6. Install thrust washer and hub nut then

tighten hub nut to specified torque

600±25

lbf-ft

. Rotate unitized hub bearing whilst

tightening. Do not stake hub nut at this

stage.

FIGURE 20: INSTALL THRUST WASHER