SECTION 18: BODY

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

23

From inside of vehicle, remove center post

and interior finishing panels surrounding the

windshield. In this case, we are replacing

the R.H. side windshield.

From outside of vehicle, remove filler

located inside rubber seal to ease damaged

windshield removal.

From inside of vehicle, push against the top

L.H. side corner of windshield for the re-

moval of a R.H. side windshield. If the L.H.

side windshield had to be removed, you

would have to push against the top R. H.

side corner.

NOTE

We are referring to the L.H and R.H. side as

viewed from the inside of the vehicle.

At the same time, another person gradually

lifts the rubber lip from the vehicle exterior

using a plastic spatula from top to bottom.

Remove the entire damaged windshield and

broken glass if applicable.

If applicable, using a screwdriver or metal

rod, remove black butyl sealant residue from

rubber seal then clean with Sika 205.

Windshield Installation

NOTE

Rubber seal may have to be replaced if it was

used on several windshield replacements.

Spray rubber seal with soapy water to

ease windshield insertion.

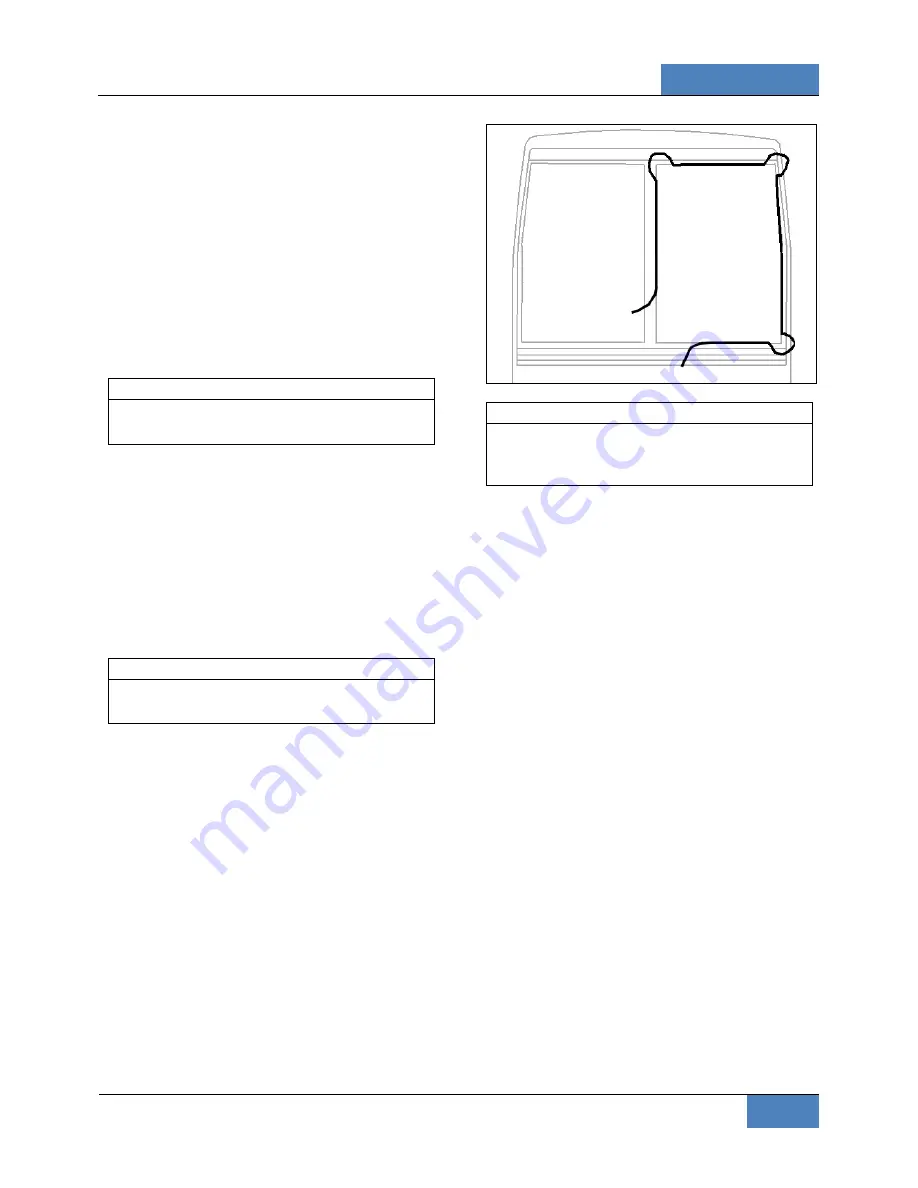

Insert rope into rubber extrusion leaving

enough length at each corner to make a

loop. Spray soapy water onto rope and

rubber extrusion (Figure 17).

Slide windshield into rubber seal groove

starting with the bottom curved side

edge. Using a plastic spatula, move the

rubber seal lip aside to gradually insert

the windshield into the groove.

Spray soapy water on a regular basis to

ease this operation.

Using the same type of plastic spatula,

repeat the same operation from inside of

vehicle, gradually inserting the wind-

shield into the groove.

FIGURE 17: WINDSHIELD INSTALLATION USING ROPE

NOTE

Make sure windshield bottom edge is well

inserted into the rubber seal groove before

proceeding with the sides.

Then, working from both sides of wind-

shield bottom to top, gradually move the

rubber seal lip aside to insert the wind-

shield into the groove. Use also soapy

water on the inside of vehicle to insert

the windshield into the rubber seal

groove.

Insert the top curved corner then finish

with the top of windshield.

At the top of windshield, clean surface

between fiberglass and rubber extrusion

using Sika 205.

Apply Sika 221 black between fiberglass

and rubber extrusion (Figure 18).

Spray filler and rubber seal groove

generously with soapy water.

Using the special filler insertion tool,

insert the filler into the rubber seal

groove.

Gradually insert filler into the rubber seal

groove ensuring to leave a 2 inch ex-

cess length at the filler extremity.

Every 6 inches or so, it is important to

compress the filler due to its tendency to

contract during drying process.

When filler insertion is almost complete,

cut filler leaving ¼” of excess length to

thwart filler contraction over time then

insert filler into groove.