SECTION 18: BODY

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

55

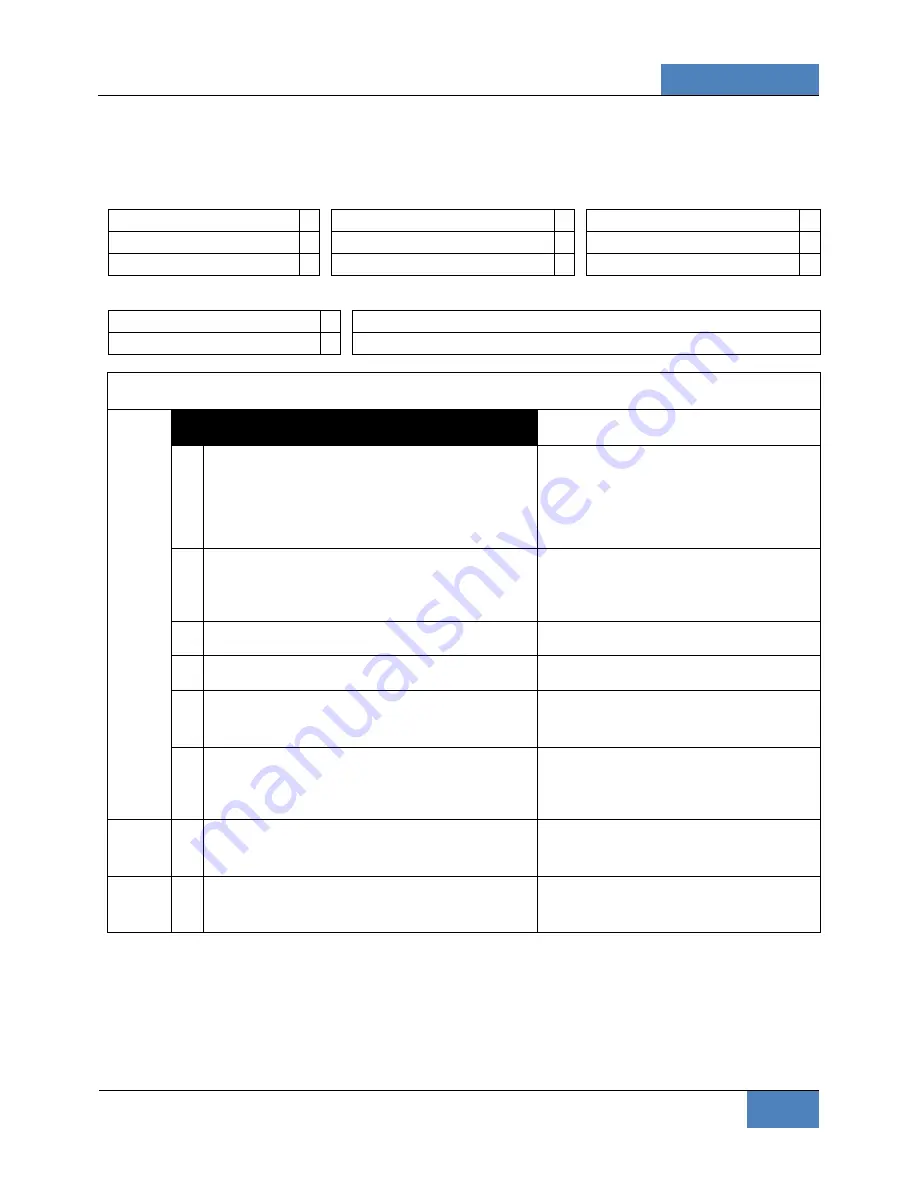

FIGURE 49: ZONE 7

18630

15.7.1 X3 SMOOTH SIDE PANEL REPLACEMENT PROCEDURE

Material:

Anti-silicone (682989)

Scotchbrite gray (680226)

Sika 221 gray

CHIX cloth (682384)

Sika 205 1liter (683097)

Sika 252 black

Blue cloth (682383)

Equipment:

Glue gun

Pencil

SECTION 1 SMOOTH SIDE PANEL REMOVAL

1.00

REMOVAL

A) Remove finishing molding. Insert a screwdriver into

snap-on finishing molding joint. Bend finishing

molding enough to be able to fix a pair of locking

pliers. Using the pair of locking pliers, pull the

stainless steel molding and at the same time

gradually cut Sika bead with a sharp knife.

Be careful not to damage the adjacent

surfaces.

B) Using a hammer and punch, drive out rivet shanks

from top and bottom and from front and rear finishing

molding supports. Use a #11 titanium drill bit to

remove rivet heads.

C)

Grind tig weld spots at each end of side panel.

D)

Safely support or temporary fix side panel.

Warning: Panel weights over 200 pounds

E)

Insert a flat screwdriver between the side panel and

the vehicle chassis, in the top left and right corners.

Make sure to separate side panel from structure.

Be careful not to damage the adjacent

surfaces.

F)

Use the c-clamp to separate the side panel from the

back structural panel and at the same time gradually

cut Sika bead with a sharp knife.

Ideally, the hoist or chain block must be

fastened to the floor while pulling from a 45

o

angle so as not to damage the vehicle

structure

G) Remove as much glue as possible from the structure

using a putty knife or pneumatic knife without

damaging 206 G+P primer.

Never heat SikaFlex adhesive to remove.

H) Check panel horizontal supports for straightness

using a straight edge. Take measurements with a

ruler.

Tolerance : 1mm towards the outside and

1.5mm towards the inside.