SECTION 18: BODY

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

69

5. Install step and press with hands. If Sika

overflows, clean with Sika 208. Repeat

previous stages for each step if applicable.

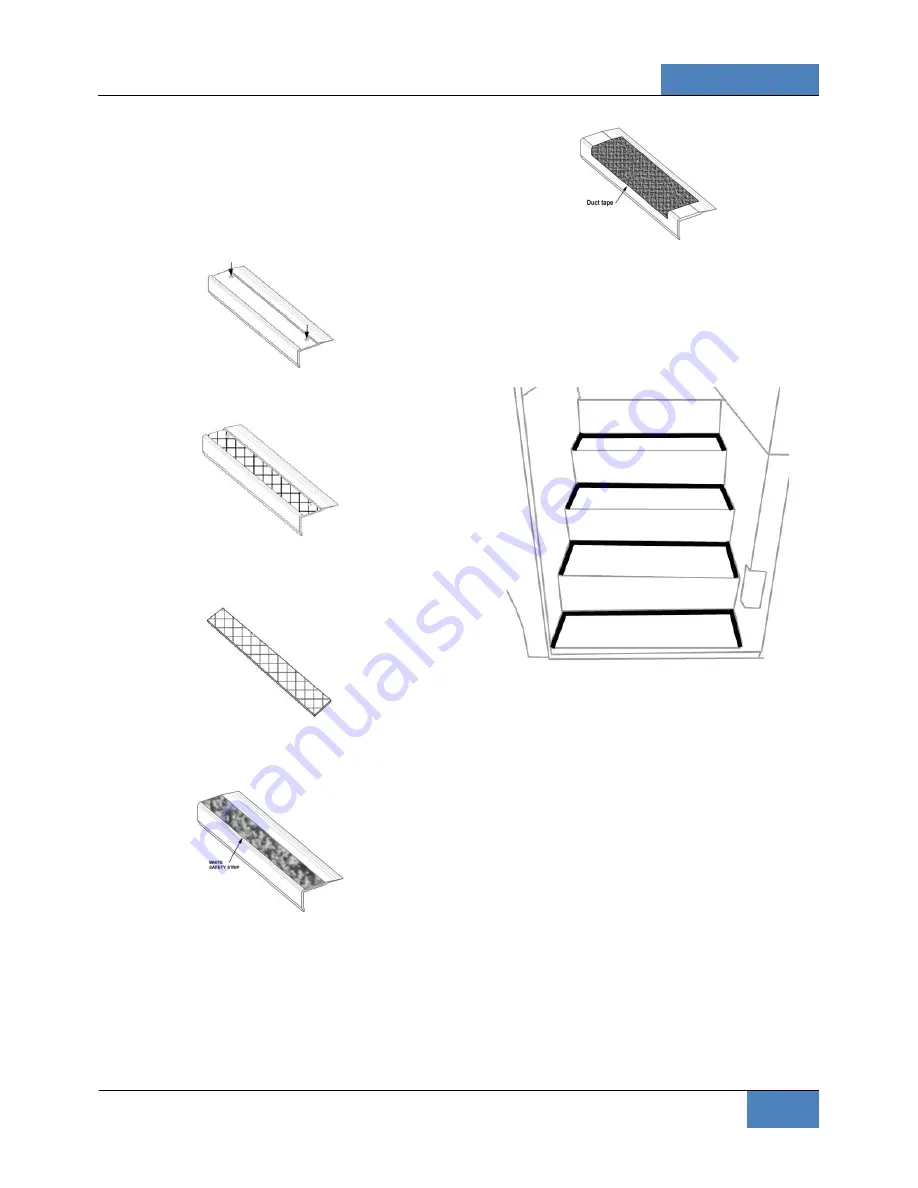

6. Remove protective film from double-coated

self adhesive tape located underneath step

nosing, position step nosing then press. Drill

and fix using screws.

7. Clean top of step nosing using Sika 205

(refer to Section B).

8. Apply some Sika 221 onto white safety strip,

spread with a spatula to cover the whole

surface.

9. Position white safety strip then press using

hands. If Sika overflows, clean with Sika

208.

10. Temporarily fix white safety strip with a

piece of duct tape, leaving 1 to 2 inches free

at each end.

11. Apply some masking tape onto the step

perimeter, clean using Sika 205 (refer to

Section B) then apply a bead of Sika 252

black. Smooth out the joints then remove

masking tape.

12. Install weights onto the steps. Minimum

waiting time: 2 hours.

18.1.1 WELDING OF JOINT BETWEEN

WHITE SAFETY STRIP AND “TARABUS”

FLOOR COVERING

1. Pre-heat welding torch;

Set welding torch to

position #4.5 (temperature of 500 °C),

Heating time: 5 minutes.

2. Before welding, visually ensure that a 1 to

1.5 mm gap exists between white safety

strip and “Tarabus” floor covering. Use a

knife if this is not the case.