SECTION 01: ENGINE

18

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

3. AUTOMATIC BELT TENSIONERS AND

IDLER PULLEYS INSPECTION

With the engine running, if noise is coming from

the tensioners or drive system, an inspection

with the engine off is necessary.

MAINTENANCE

Remove belts and inspect automatic belt

tensioners, idler pulley bearings every 30 000

miles.

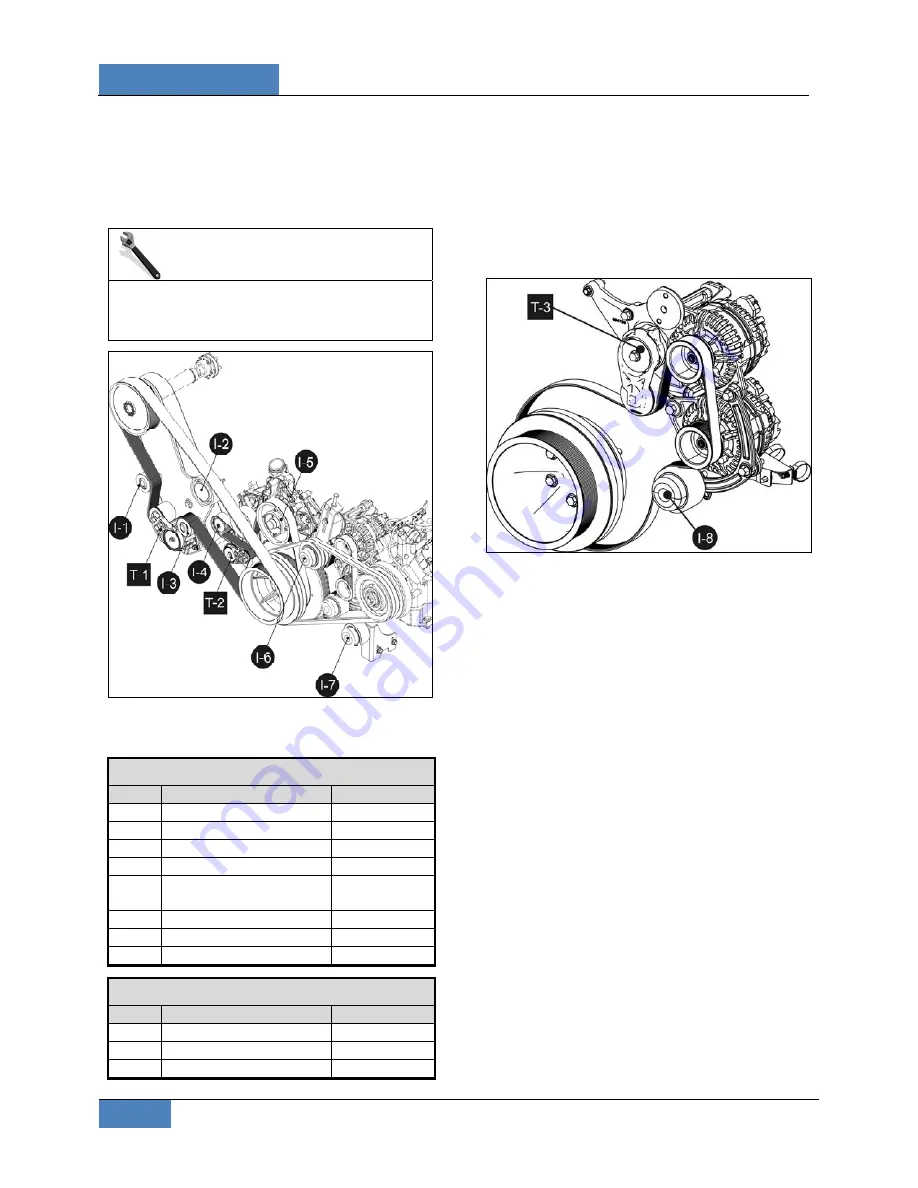

FIGURE 14: IDLER PULLEYS AND AUTOMATIC BELT

TENSIONERS ON COOLING FAN DRIVE, WATER PUMP

DRIVE AND A/C COMPRESSOR DRIVE

I

DLERS

Ref

System

Torque lbs-ft

I-1

cooling fan drive

50

I-2

cooling fan drive

35

I-3

cooling fan drive

50

I-4

water pump drive

43

I-5

water pump drive

16 (pulley)

32 (shaft)

I-6

A/C compressor drive

35

I-7

A/C compressor drive

82

I-8 alternator

drive

82

AUTOMATIC BELT TENSIONERS

Ref

System

Torque lbs-ft

T-1

cooling fan drive

32 (2x)

T-2

water pump drive

43

T-3 alternator

drive

43

3.1 BEARING INSPECTION

1. First, set parking brake, turn the ignition

OFF and set the rear start selector switch to

the OFF position.

2. Remove all belts on cooling fan drive, water

pump drive, A/C compressor drive and

alternator drive.

FIGURE 15: IDLER AND AUTOMATIC BELT TENSIONER

ON ALTERNATOR DRIVE

3. Spin all idler pulleys, I-1 thru I-8, plus the

idlers that are part of the automatic belt

tensioners T-1 thru T-3.

4. Listen if some idlers are noisy and check for

play in the bearings by hand.

5. Replace noisy idlers or if a play is found.

Replace the automatic belt tensioner as a

complete unit.

6. Record the results of the inspection.

3.2 AUTOMATIC BELT TENSIONER

BUSHING WEAR

Automatic belt tensioner bushing wear may

results in belt misalignment.

1. Check the automatic belt tensioner T-1 thru

T-3.

2. Pry the automatic belt tensioner arm and

check for a play between the arm and the

spring case (see image below).