SECTION 22: HEATING AND AIR CONDITIONING

20

DOB 2490-2789 | X3-45 Commuter PA1605 Maintenance Manual (Final Version – Rev.2 April 2016)

no attempt should be made to correct the

leaks by tightening the connections beyond

the recommended torque. The O-rings are

designed to seal at the specified torque and

overtightening the connection does not

result in a satisfactory and permanently

sealed connection. The connection must be

disassembled and the cause of the leak

(damaged O-ring, defective lines, etc.)

corrected. Use new O-ring.

6.3 PUMPING

DOWN

This procedure is intended to reduce refrigerant

loss by isolating it in the compressor and

receiver tank, as well as in their connecting line,

in order to carry out repairs on other sections of

the air conditioning system (lines and

components).

NOTE

Once this pull down procedure has been

properly done, any component from the outlet

hose on the receiver tank, the filter-dryer, the

liquid solenoid valves, the evaporators, the

expansion valves, and all lines associated with

them can be serviced, then properly

evacuated.

It must be noted that there is STILL refrigerant

under pressure in the compressor, the

discharge lines, condenser, and receiver tank

and that these items cannot be serviced. To

service these items, it is required to recover

the refrigerant using a recovery unit.

CAUTION

The filter-dryer must be replaced after a

severe system failure or if a line in the

system has been opened over a prolonged

period of time. The line will then have to be

properly evacuated.

Best practice would be to replace the filter-

dryer each time a line is opened.

NOTE

Before attempting any repair between

compressor and receiver tank, use a recovery

unit to remove refrigerant from the system.

WARNING

To prevent any injury, when air conditioning

system must be opened, refer to previous

paragraph “PRECAUTIONS IN HANDLING

REFRIGERANT”.

NOTE

For this procedure to be done properly, it is

assumed the proper amount of refrigerant is in

the refrigeration system. If there is any doubt,

use a recovery unit to recover and weight the

amount of refrigerant in the system.

6.3.1 Procedure

1. Energize driver’s unit and passengers’ unit

(main HVAC system) section liquid solenoid

valve. To do so, connect male and female

connector housings of C24 together for the

passengers’ area (found on the HVAC

module in evaporator compartment) and

C44 for the driver's area (located on the

ceiling of the spare wheel compartment).

During normal use, both male and female

housings of connector C24 or C44 are kept

unplugged.

CAUTION

Connectors C24 & C44 must be disconnected

and their caps reinstalled after this procedure.

Leaving them connected will keep the driver’s,

passengers’ and parcel rack liquid solenoid

valves open, and result in battery draining if

the vehicle remains unused for several days.

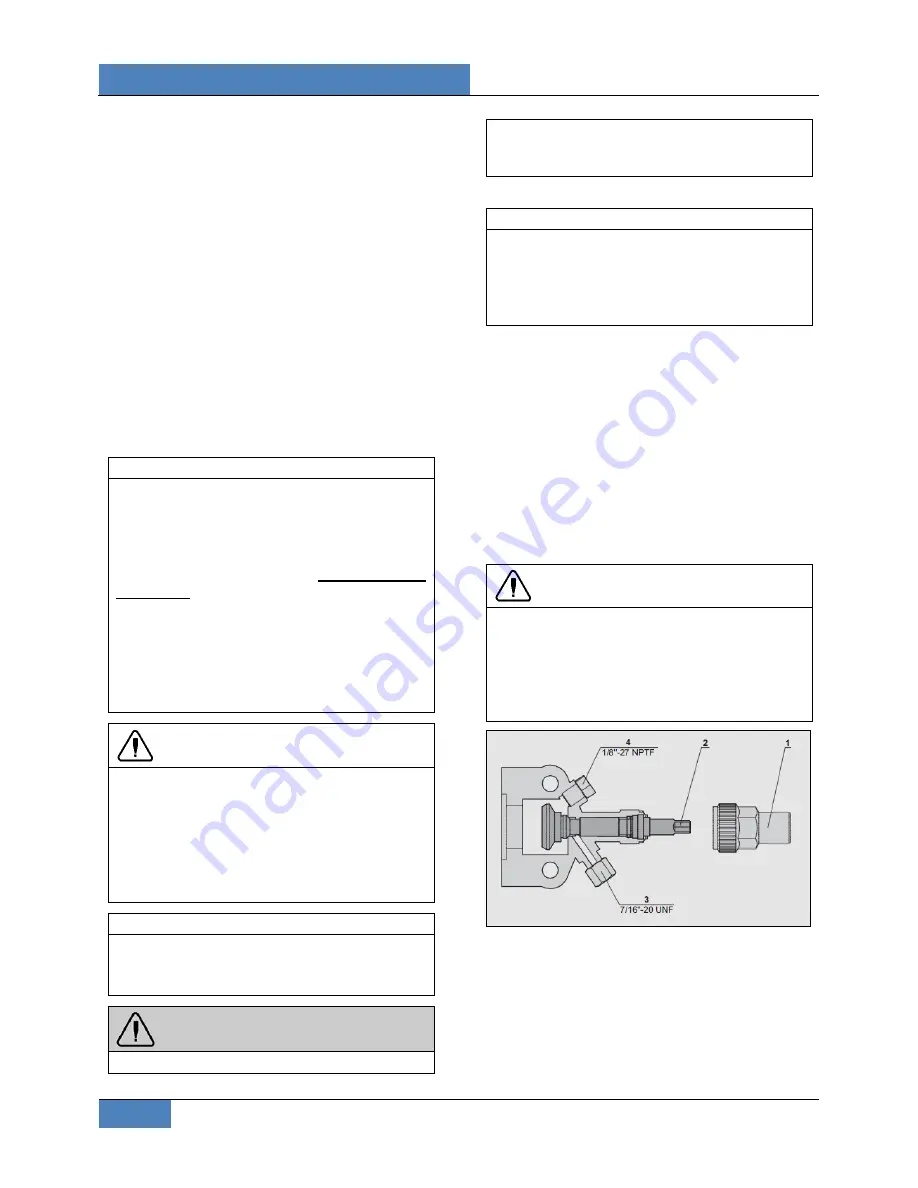

FIGURE 20: COMPRESSOR SHUT-OFF VALVE

BACKSEATED POSITION (NORMAL OPERATING

POSITION)