T.O.2

| 28

Inspection and Adjustment

5 Inspection and Adjustment

5.1 Tubular Vial

Inspection

1. Fix the instrument to the tripod and roughly level up the instrument and make the

tubular vial parallel to the connecting line of two of the three leveling screws on the

base. Adjust the two leveling screws so that the tubular vial is centered.

2. Turn the instrument 180° and check if the water bubble remains at the center.

3. If the water bubble remains at the center, no adjustment is required; otherwise,

perform adjustment as follows.

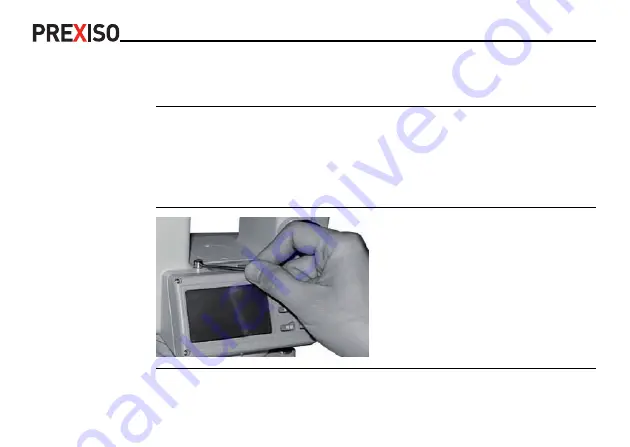

Adjustment

1. Adjust the bubble adjusting screw so

that the bubble moves toward tube

center for half the off-center.

2. Turn the leveling screw to correct the

other half off-center so that the bubble

stays at the center.

3. Repeat the steps in "Inspection" and

"Adjustment" until the long water level is

centered when the instrument is at any

position.