fit I system track installation prep

Follow all local and national electrical codes.

For assistance please call Prima Customer Ser

vice at 562-407-3079

A1

A2

IMPORTANT Please read these instructions prior to installation. Refer to the Prima catalog for proper lamp type and maximum wattage for fixtures.

Prima is not responsible for any fixture or system failure caused by unsupported lamps. Contact Prima customer service for the latest updates on

which lamps we support and proper usage. Prima low voltage transformers must be used with all Prima Lighting product installations. All warranties

are void if Prima transformers are not used. Prima’s catalogs provide general information and suggestions for proper dimmer usage. Please consult

our customer service department with any questions regarding dimmer specifics. Prima is not responsible for any damage caused by improper

dimmer specification and usage. Use only qualified electrician for installation. Adhere to all local and national electrical codes prior to installation.

It is strongly recommended that gloves are used when handling the FIT I System track. Oils and dirt from fingers can sometimes permanently

mark the finish. Track should be cleaned with a damp cloth and thoroughly dried before fixture installation.

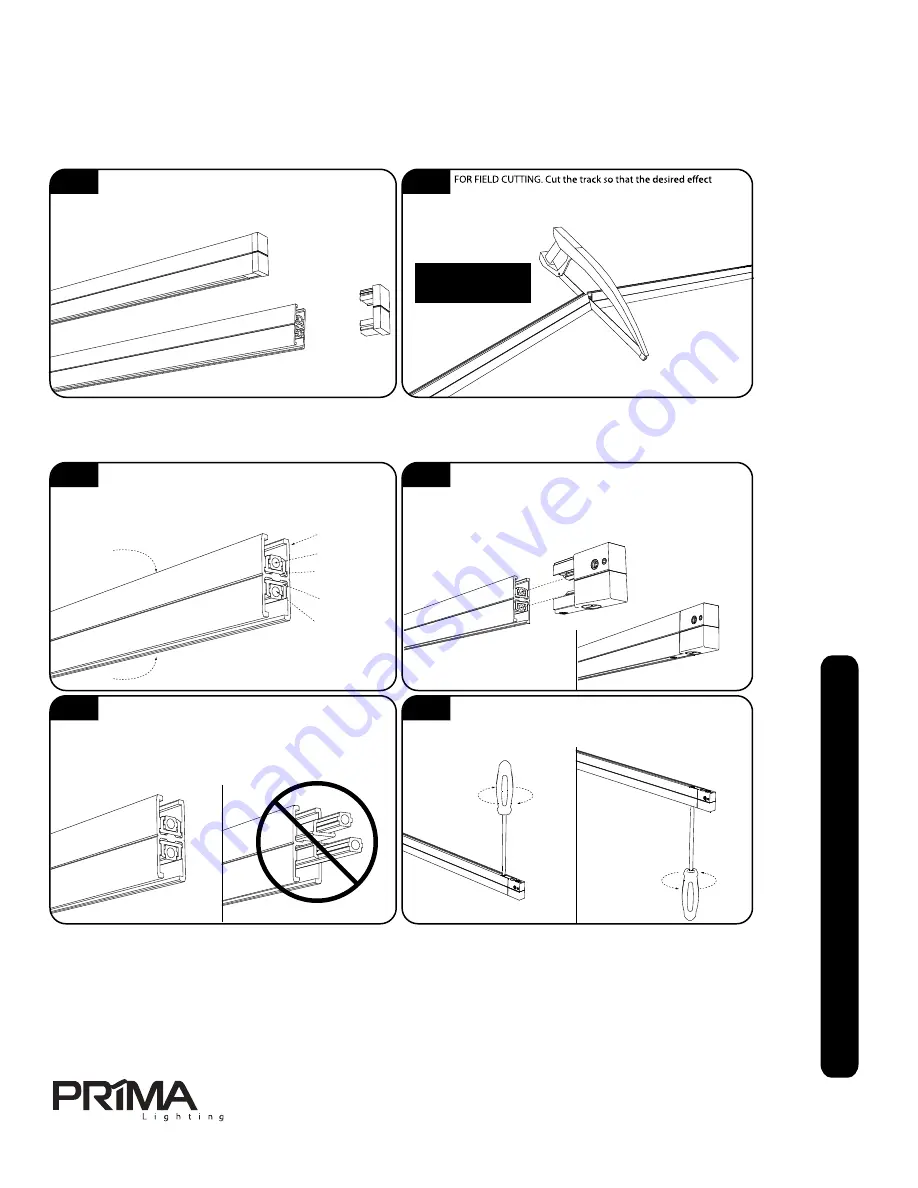

Determine whether the FIT I track length will be installed as

part of a series of connected track lengths or as a single

stand alone track length. Before attempting to field cut the FIT I track,

ensure that the end caps are firmly installed into both ends. If an end

cap has become loose during shippping, replace it.

and lengths can be achieved. FIT track may be field cut with

an ordinary hacksaw. Be sure to use a FINE-TOOTH METAL CUTTING

BLADE. Be sure to deburr and clean all cuts prior to final assembly.

fit I system track connector/powerfeed basics

B1

B2

Connectors are available for extending track length, turning corners or creating intersections in the run. Great care must be taken to ensure

the connector is installed properly.

FIT I track is constructed of an aluminum housing which

doubles as the neutral conductor. Each of the two slots of the

track include one conductor and one insulator. The slots may used as

two separate circuits with the proper use of powerfeeds. The track may

also be configured as one circuit for both slots with the use of a jumper.

When installing a connector or powerfeed, place the opposite

end of the track length against a solid flat surface to keep the

internal parts of the track from sliding. Carefully align the connector pins

on the connector with the holes in the track’s conductors. Insert the

connector all the way into the track until it stops.

Track housing/

Neutral

Conductor 1

Insulator 1

Slot 1

Slot 2

Conductor 2

Insulator 2

B3

B4

When installing a connector at the end of a FIT I track length,

great care should be taken to ensure the connector is properly

installed. After the connector has been inserted into the end of the track,

inspect the opposite end of the track. If the inslulators and conductors

are flush with the end, then the installation was successful. If the

conductors protrude past the end of the track AT ALL then connector is

not properly installed.

When the connector or powerfeed is properly inserted into the

track length, secure the installation by tightenting the lock

screws located at the top and bottom of connector. DO NOT

OVERTIGHTEN THE SCREWS.

Opposite end after a

proper connector installation.

Opposite end after an

improper connector installation.

FIT SYSTEM TRACK

MAY NOT BE BENT IN

ANY WAY

FIT I System track

may not be bent

13615 Marquardt Ave. Santa Fe Springs, CA 90670

Ph. 562-407-3079 . Fx. 562-407-3069

www.primalighting.com

*Caution:

Do not break the insulator inside

the chamber while using the

screw-in function. Broken insulator

will cause short of circuit.

*Caution

REV

.033015

prima fit I system

general installation instructions part 1 of 12