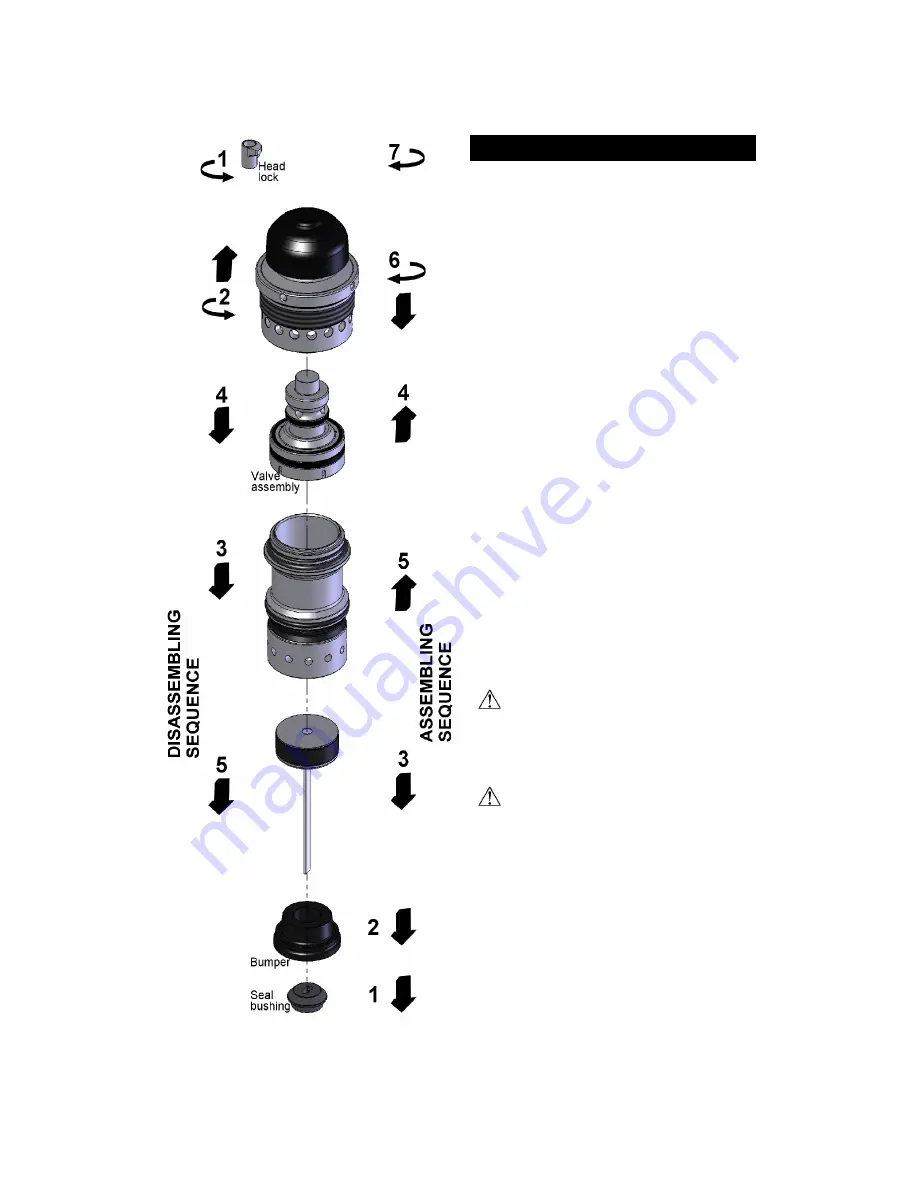

ASSEMBLING THE TOOL

This section describes how to re-assemble the tool after

maintenance. The following procedure assumes that the

gate/foot assembly along with the resting block are

already installed.

[1] Insert the seal bushing in the lower section of main

body and engage it onto the upper portion of the

gate/foot assembly. A flat screwdriver can help locate

it correctly. Use the wooden handle of the hammer to

tap the seal bushing completely in place.

Note: select the appropriate seal bushing:

- use P-525B for the "L" or "T" nailers

- use P-525C for staplers

[2] Check & lubricate the valve assembly. Insert into the

head and ensure that it is sliding easily.

[3] Snap the cylinder onto the head. Check that the band-

valve on the cylinder is properly installed.

[4] Insert the piston assembly about 1" into the bottom

end of the cylinder.

[5] Push the bumper into the bottom end of the cylinder.

[6] With the head lock loosened, engage the whole

assembly into the tool, with the driving blade engaged

thru the opening of the seal bushing. Depress the

safety contact and engage down completely into

gate/foot assembly guiding channel.

Insert the Alen key into one of the side holes and

screw the head assembly completely. Take care not

do damage the threads. Tighten by hand.

NEVER apply threadlocker or adhesive onto

head threads.

[7] Rotate the head lock clockwise and tighten with

moderate force with the Allen key.

After reassembly, always actuate the tool

repeatedly WITHOUT FASTENERS against a

piece of wood to insure proper operation.