5

4

SAFETY

SAFETY

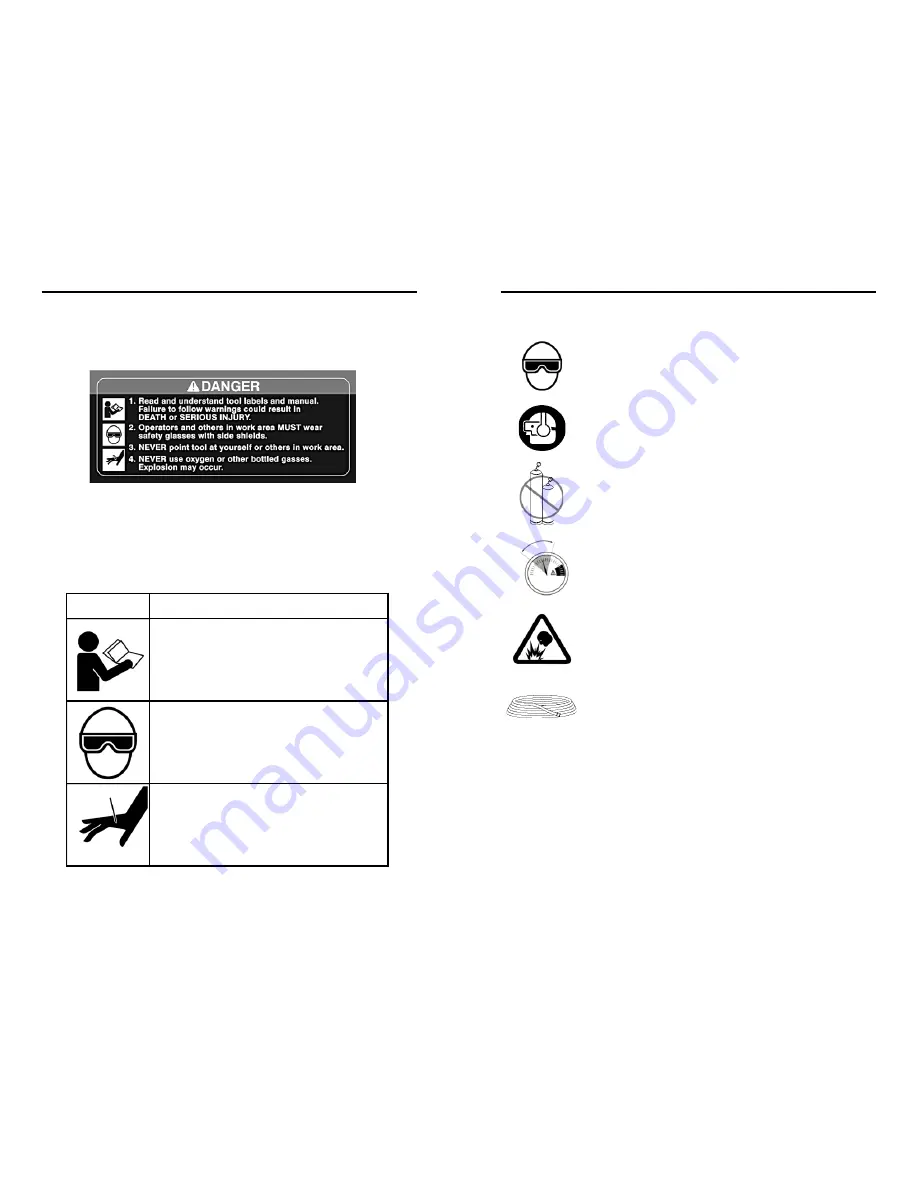

SAFETY LABELS

This pneumatic fastening tool includes a warning label to help remind you of

important safety information when operating the tool. The safety label must be

legible at all times, and must be replaced if it becomes worn or damaged.

SAFETY SYMBOLS

The safety symbols on the safety label provide a visual reminder of

basic safety rules, and the personal injury hazard that may arise if

all safety and operating instructions are not followed. Make sure

you understand the meaning of each of these symbols, and protect

yourself and others by obeying all safety and operating instructions.

SYMBOL

DESCRIPTION

READ THE MANUAL

- The manual contains

important safety and operating instructions

that must be followed. All tool users must

read the manual before using the tool.

WEAR SAFETY GLASSES

- Tool operator

and bystanders must wear safety glasses

with side shield that meet ANSI Z87.1

requirements.

RISK OF PERSONAL INJURY

- Failure to

follow all safety and operating instructions,

or misuse of the tool, can result in serious

injury to tool operator and bystanders.

WEAR SAFETY GLASSES

Always wear safety glasses with side shields that meet ANSI

Z87.1 requirements when operating the tool. Make sure all

others in work area wear safety glasses.

WEAR HEARING PROTECTION

Wear hearing protection to protect your hearing from noise.

Prolonged exposure to loud noise can result in hearing loss.

NEVER OPERATE THE TOOL WITH OXYGEN OR OTHER

BOTTLED GASES

Oxygen and other reactive or high-pressure bottled gases

can cause the tool to explode. Use clean, dry regulated

compressed air from a properly operating air compressor.

DO NOT EXCEED MAXIMUM RECOMMENDED OPERATING AIR

PRESSURE OF 120 PSI /8.3 Bar.

Exceeding the maximum recommended air pressure can

cause the tool housing to burst, or cause premature failure of

components.

NEVER CONNECT THE TOOL TO AN AIR SUPPLY THAT HAS

THE POTENTIAL TO EXCEED 180 PSI/12.4 Bar.

Using a regulated air supply with a line or tank pressure

greater than 180 psi can cause the tool to burst if the air line

regulator fails suddenly.

USE AN AIR HOSE RATED FOR 180 PSI/12.4 Bar OR

GREATER

Always use air hose rated to handle 180 psi or the maximum

potential pressure of the air supply.

ONLY USE A RELIEVING-TYPE AIR COUPLING IN THE TOOL

AIR INLET OPENING.

Use of a non-relieving air coupling on the tool can trap air

inside the tool housing, and allow the tool to drive a fastener

even after the air hose has been disconnected.

SAFETY INSTRUCTIONS

120 psi

6.9 bar

100 psi

8.3 bar