17

16

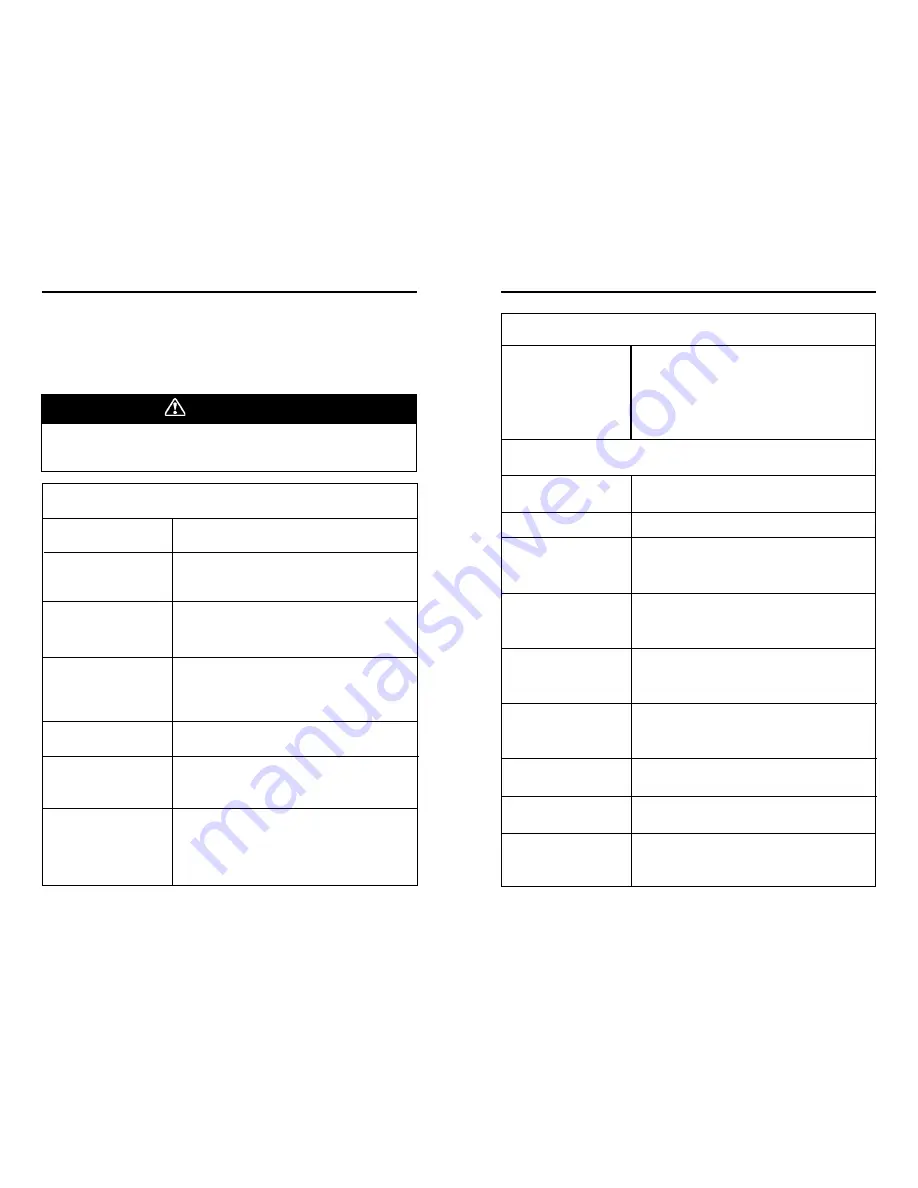

TROUBLESHOOTING

TOOL TROUBLESHOOTING

Your pneumatic fastening tool has been designed for long life and trouble-

free operation. However, if operating problems arise, please use the

troubleshooting information below to determine how to remedy the prob-

lem.

TROUBLESHOOTING

Fastener jammed in

tool nose, preventing

tool from operating.

Depress magazine release, and open maga-

zine. Remove jammed fastener, and check

magazine for obstructions, debris, and loose

fasteners. Discard loose fasteners. Clean

fastener track as required, and reload fasten-

ers.

PLASTIC CAP PROBLEMS

Caps are not applied

Check cap tower and reload if necessary

Caps feed, but are not

retained in fastening

position.

Flipper arm worn or broken. See dealer for

repair.

Cap tower full, and

driver link is aligned,

but caps do not feed.

Open cap tower door and push cap stack

down firmly. Close door and drive a fastener

to eject cap.

Cap tower full, but

caps do not feed into

fastening position.

Check cap driver hook for proper positioning

as shown on alignment label. Reposition if

necessary.

Caps do not feed - cap

appears jammed in

magazine.

Remove jammed cap through opening in front

plate.

Caps not tight against

work surface.

Increase air pressure. Make sure tool is held

against work surface when driving fastener.

Caps cut or deformed

by fastener.

Fastener position on

cap off-center

Decrease air pressure.

Avoid dragging tool against work when

applying caps. Keep tool stationary when

fastener is being driven.

CORRECTIVE ACTION

PROBLEM

Fasteners do not drive

completely.

Increase air pressure. Add 2 - 3 drops of air

tool oil to inlet. Do not exceed 120 psi/8.3

bar

Fasteners do not drive

completely when

driving in quick succes-

sion.

Inadequate air flow. Use larger diameter hose.

Use compressor with larger storage tank.

Keep hose lines short. Check air hose for

kinks or other restrictions.

Fasteners drive too

deeply.

Reduce air pressure. (Do not reduce air

pressure below 100 psi/6.9 bar.)

Tool operates, but no

fastener is driven.

Check fasteners for smooth feeding in

magazine. Check magazine for obstructions

or debris, and clean as required.

Tool leaks air.

Check for source of leak, and tighten fittings

and screws as required. Discontinue using

tool if air leaks at trigger area or from cap

exhaust. Contact your dealer.

PROBLEM

CORRECTIVE ACTION

Fasteners do not drive

completely after air

pressure is increased.

Driver blade worn or broken. See dealer for

replacement.

FASTENER DRIVING PROBLEMS

FASTENER DRIVING PROBLEMS

Always disconnect tool from air supply before performing any service on

tool. Correcting a problem while the tool is pressurized may result in

injury from fastener discharge or tool operation.

DANGER