4

INTRODUCTION

To simplify the use and maintenance of your new air compressor and ensure a long trouble-free life from your

compressor, please read the following:

DO NOT TRANSPORT COMPRESSOR UNDER PRESSURE!!!

ALWAYS USE IN WELL-VENTILATED AREA

DO NOT USE NEAR OPEN FLAMES OR FLAMABLE LIQUIDS

BEFORE USE:

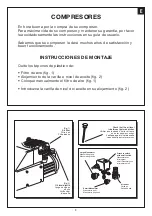

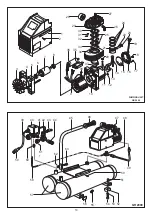

Before using your compressor, follow these simple steps:

-

Remove plastic plugs from cylinder head and oil plug.

-

Screw air filter in cylinder head and place oil dipstick in crankcase of compressor.

-

Check for correct oil level.

-

Ensure compressor is placed on flat surface in well ventilated area.

POWER SUPPLY AND EXTENSION CORD GUIDE:

Check for proper voltage 110V 60Hz (220V will burn motor).

Extension cords can cause low amperage damage to the motor.

Extreme caution should be taken when using extension cords.

STARTING YOUR COMPRESSOR

Before connecting to the power supply, ensure on/off switch is in off position.

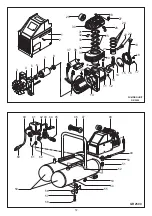

SETTING THE PRESSURE REGULATOR:

After compressor has filled up air tanks, turn red knob clockwise to increase pressure to desired level shown on

pressure gauge of regulator. To decrease pressure, turn red knob counterclockwise.

MAINTENANCE

After the first 50 working hours or 30 days, whichever comes first, replace oil with a non-detergent compressor

oil, 10-30 or 40 weight depending on weather conditions.

-

Check all nuts and bolts for proper tension.

-

Blow out air filter with compressed air.

-

Blow out cylinder head to ensure proper cooling.

DAILY

-

Check oil level befor use (Low oil is largest cause of problems).

-

Drain air tanks after each working day.

-

Blow off any dust or dirt form cylinder heads to ensure proper cooling.

WEEKLY

-

Check for loose bolts-adjust if needed.

-

Clean air filter.

EVERY 300 WORKING HOURS OR 3 MONTHS

-

Change oil.

-

Clean air filter.

-

Check for air leaks and correct as needed.

-

Clean compressor head for proper cooling.

-

Check all bolts for proper tightness.

CHANGE OF SEASON

-

Change oil to proper weight-10 weight in winter/30 or 40 weight in summer, depending on outside temperatures.

(Use 40 weight if over 90 F).

-

Store compressor in warm dry space (above freezing).

FOLLOW THESE GUIDELINES TO MINIMIZE DOWN TIME AND MAXIMIZE THE LIFE OF YOUR AIR COMPRESSOR.

SAFETY AND GENERAL WORKING INSTRUCTIONS.

The air compressor must he used in a suitable environment (good ventilation).

The area in which the compressor is operated must be free from acids, vapor, explosive gasses and flammable or

unstable materials.

GB