5

When using the electrically-operated equipment, certain fundamental rules must be obeyed:

-

Do not touch the machine with wet hands or while barefooted.

-

Do not pull the compressor by electrical cord-use only the handle.

-

Do not attempt to remove the plug by pulling on electrical cord.

-

Do not allow children or inexperienced operators to use the equipment.

-

Do not clean the machine with solvents or flammable liquids-use only soapy water, but never on the electrical

components.

-

Use suitable plugs and sockets (according to specification and with proper circuit protection and grounding).

-

Use only with air-no other gasses can be used.

-

Do not pull rubber hoses to move the compressor. Compressed air is an energy fluid and, therefore, is potentially

dangerous. The air hoses carrying compressed air must be suitably fixed, especially rubber hoses. If not properly

fixed they can cause damage or injury.

-

Never aim compressed air toward yourself or any others. Remember that use of protective glasses is necessary

for protecting your eyes from dust and other particles moved by compressed air.

-

Do not use compressed air to fill cylinders for breathing/diving apparatus.

Compressed air from cannot be used for pharmaceutical, food or health functions without further treatment.

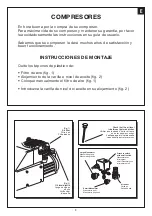

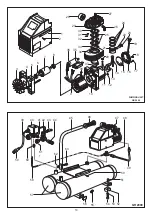

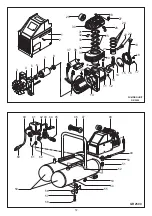

WORKING DETAILS - SAFETY VALVE - PRESSURE SWITCH

PUMP – NON-RETURN VALVE – TANK – PRESSURE REDUCER – USER

The pump produces compressed air which goes into the air tanks through the delivery pipe and the non-return

valve. When the air pressure arrives at the factory-set pressure of 135 p.s.i. the pressure switch shuts off the supply

to the axial electric motor, which stops and at the same time discharges the air held in the cylinders and in the

delivery pipe through the rilsan tube and pressure switch. In this same way, the pump is depressurized and can

easily restart when the pressure in the air tanks falls below the minimum fatory-set pressure of 105 p.s.i. The

pressure switch is

supplied with a discharge valve which reduces strain on the pump and motor during startup.

TROUBLESHOOTING

CAUTION!!! TO AVOID INJURY WHEN SERVICING COMPRESSOR, ALWAYS ENSURE AIR TANKS ARE DRAINED

AND POWER IS DICONNECTED BEFORE YOU START.

LOW PRESSURE

-

Check for air leaks and correct if needed

-

Leaking valves

-

Blown gaskets

-

Worn rings

AIR LEAKS FROM PRESSURE SWITCH

If air leaks through pressure switch after compressor shuts off or switch is in off position (leak stops when switch

is in on position), remove top nut of check valve (valve located on air tank where air pipe is connected), clean any

dirt or debris from rubber membrane and housing. Reassemble and check for leaks. If leak continues, you may

have to replace a faulty pressure switch.

Before opening check valve, ensure air tank are drained to avoid serious injury.

COMPRESSOR KNOCKS

-

Check for proper oil level.

COMPRESSOR DOES NOT START

-

Check pressure in air tank (Compressorwill not start if pressure is too high)

-

Check pressure switch

-

Check thermal overload switch

-

Check power supply

-

Check for loose wires

-

Take compressor to an authorized service center

TO PROLONG THE LIFE OF YOUR COMPRESSOR ALWAYS

1. CHECK PROPER OIL LEVEL

2. USE CORRECT POWER SUPPLY AND EXTENSION CORDS

3. KEEP CYLINDER AND HEAD CLEAN TO ENSURE PROPER COOLING

4. NEVER RUN COMPRESSOR WITHOUT AIR FILTER

5. DRAIN AIR TANKS AFTER EACH WORKING DAY