Instruction Manual VARORMAT

7

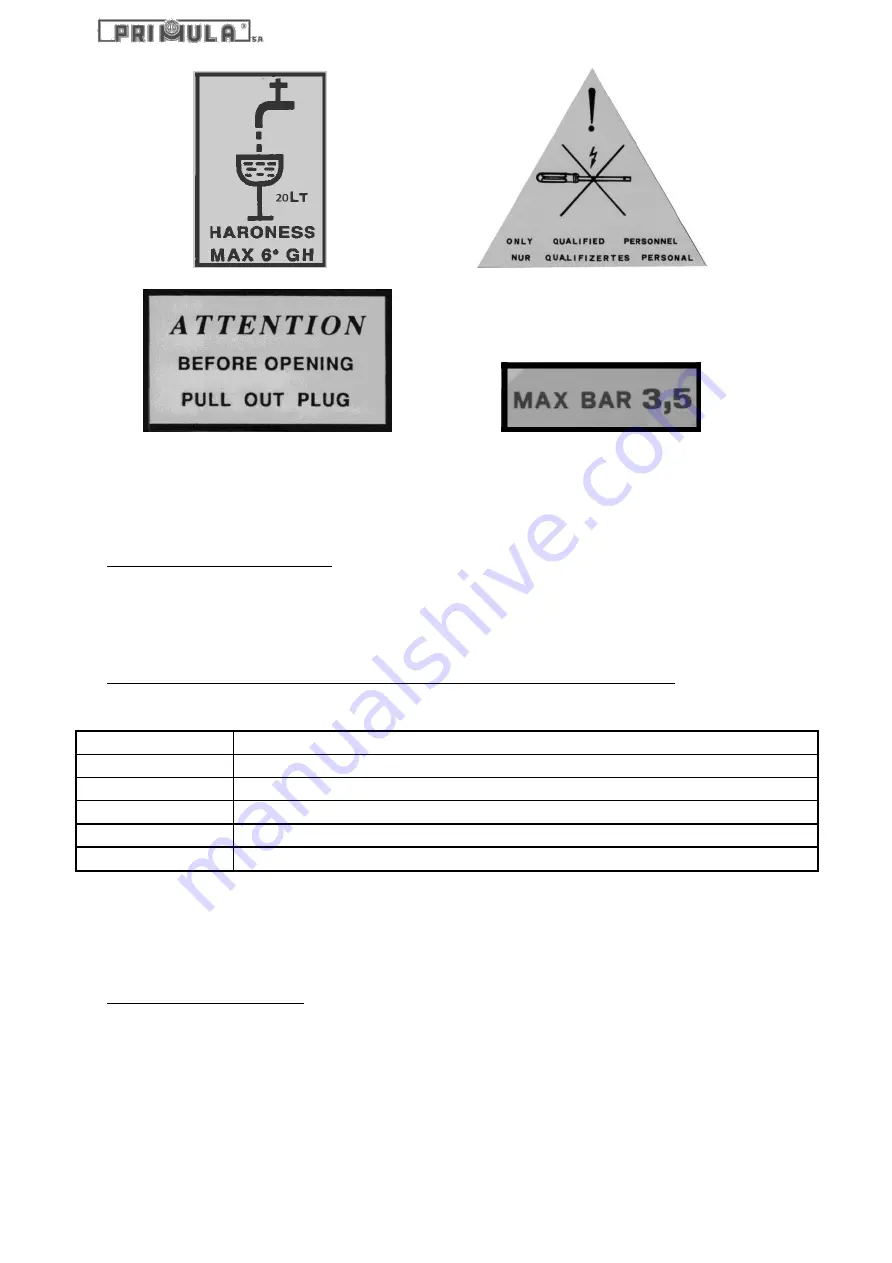

The operator of the system has the obligation to inform himself regarding the dangers which

may occur during usage, so that he/she can avoid them or minimize their occurrence as best

as he/she is able to

.

4.Instrutions for installation

4.1

Installation

The machine is ready to work. Just place it to the requested position and connect it to

the power.

The good operation of the machine is depended of the feedwater formation.

Feedwater requirements:

Hardness

less than 100mg/las CaCO or less than 6 German degrees

PH

7-8

CO

No free CO allowed.

TDS

less than 200mg/l.

Fe

None

Suspended solids

Water should be clear and free from suspended solids, colloids, alcal, ect

In case that the hardness of the water is more than the above requirements, it is

recommended to use ANTISCAL. The lime contained in the water may be placed in the boiler

and on the heating elements will cause faults. The use of ANTISCAL prevents deposits of lime.

4.2 Electrical Connection

For the electrical connection and all for the power supply, please follow carefully the

instructions of the wiring diagram (enclosed) as well the WARNING symbols, attached to the

machine.Connect the machine to the power supply through the plug Nο 47 (see images of

the spare parts on page 13) . If power supply is 230Volt/1phase, the connection must be

done ,in a 3-poles socket plug (1 phase, 1 neutral, 1 ground). The power must be insured by a

2-poles (25 Amber) fuse.

CAUTION! For your own safety, pay attention to all the warning labels (yellow coloured) that

are placed on the machine. The manufacturer bears no liability for any damages or accidents

due to faulty supplying network or to not specified personnel.