52

516514

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

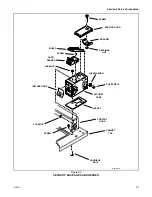

42. BURNER SYSTEM COMPONENTS

(GAS MODELS)

a. Complete Gas Valve Assembly.

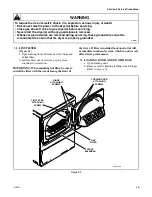

(1) While supporting the access panel, remove

two screws from bottom edge of access

panel. Refer to Figure 7.

(2) Gently lower the access panel to disengage

locators from bottom edge of front panel.

Refer to Figure 37.

(3) Close main gas shut-off valve.

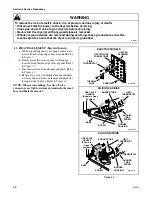

(4) Silicon Carbide Ignition – Disconnect

igniter wires at disconnect blocks, sensor

wires from sensor terminals, and wires

from gas valve coils at the quick disconnect

blocks. Refer to Figure 39.

Silicon Nitride Ignition – Disconnect wire

harness from igniter and sensor assembly,

and from gas valve coils at disconnect

blocks.

(5) Disconnect gas shut-off valve from gas

valve at the union nut. Refer to Figure 39.

(6) Remove three screws holding valve and

mounting bracket to base. Refer to

Figure 39.

(7) Lift gas valve and mounting bracket from

base. Refer to Figure 39.

NOTE: The holding and booster coil, and secondary

coil can be replaced individually.

b. Burner Tube, Igniter and Bracket

NOTE: Burner tube and igniter can be removed

without removing gas valve and bracket.

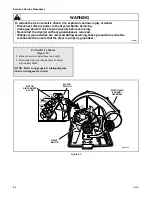

(1) Remove one screw from right side of

burner housing holding burner tube in

place. Refer to Figure 41.

(2) Gently move burner tube toward rear of

dryer to disengage tab from slot on left side

of burner housing. Refer to Figure 39.

(3) Carefully rotate burner tube and igniter

counterclockwise so tab is at 8 o’clock

position.

(4) Move air shutter end of burner tube slightly

to right and CAREFULLY remove burner

tube and igniter assembly out through front

of dryer.

(5) Remove screw holding igniter and bracket

to burner tube and remove igniter and

bracket. Refer to Figure 41.

IMPORTANT: Use care while removing igniter to

avoid damaging or breaking it. The igniter is very

fragile.

IMPORTANT: Handle igniter by grasping the

white ceramic portion of bracket only. DO NOT

handle silicon carbide portion of igniter with hands

or allow any oil, grease or other foreign material to

contaminate it. Oil, grease and other impurities or

hairline cracks will cause the igniter to burn out.

c. Ignition Control

(1) Remove access panel as indicated in

Paragraph 19.

(2) Remove wire harness from ignition control.

(3) Remove screws holding ignition control to

bracket. Refer to Figure 41.

(4) Carefully remove ignition control. Refer to

NOTE: For information on ignition control flashes,

Refer to Paragraph 14.

d. Sensor

(1) Remove access panel as indicated in

Paragraph 19.

(2) Remove wires from sensor and igniter

terminals. Refer to Figure 39.

(3) Remove screw holding igniter and sensor

to burner housing. Refer to Figure 39.

Summary of Contents for DAM 9

Page 1: ...DAM 9 SERVICE MANUAL INDUSTRIAL DRYERS PUBLICATION DATE 02 01 516514 ...

Page 2: ......

Page 127: ......

Page 128: ......