516514

57

Section 5 Service Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

43. BURNER HOUSING AND HEAT SHROUD

(Gas Models)

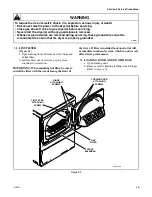

a. While supporting the access panel, remove two

screws from bottom edge of access panel. Refer

to Figure 7.

b. Gently lower the access panel to disengage

locators from bottom edge of front panel. Refer

to Figure 37.

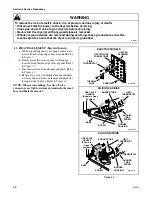

c. Silicon Carbide Ignition: Disconnect igniter

wires at disconnect blocks, sensor wires from

flame sensor terminals, and wires from gas

valve coils at the quick disconnect blocks.

Refer to Figure 39.

Silicon Nitride Ignition – Disconnect wire

harness from igniter and sensor assembly, and

from gas valve coils at disconnect blocks. Refer

to Figure 39.

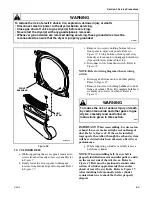

d. Remove screw from right side of burner

housing, while holding burner tube in place.

Refer to Figure 43.

e. Gently move burner tube toward rear of dryer to

disengage tab from slot on left side of burner

housing. Refer to Figure 39.

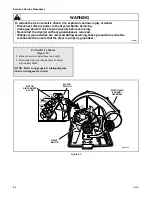

f. Carefully rotate burner tube and igniter

counterclockwise so tab is at 8 o’clock

position.

g. Move air shutter end of burner tube slightly to

the right and CAREFULLY remove burner

tube and igniter assembly out through front of

dryer.

IMPORTANT: The igniter is very fragile. Be careful

not to damage it during removal.

h. Remove screw holding burner housing to heat

shroud. Refer to Figure 39.

i. Remove screw holding front of burner housing

to dryer base and remove housing out through

front of dryer. Refer to Figure 43.

j. Remove two screws holding heat shroud to

heater box and take heat shroud out through

front of dryer.

44. LIMIT THERMOSTAT

a. While supporting the access panel, remove two

screws from bottom edge of access panel. Refer

to Figure 7.

b. Gently lower the access panel to disengage

locators from bottom edge of front panel. Refer

to Figure 37.

c. Disconnect wires and remove screws holding

limit thermostat to burner housing (gas models)

or element plate (electric models). Refer to

Figure 43.

d. Repeat procedure on models with more than

one thermostat.

To Test Heater Assembly

(Electric Models)

1. Disconnect wires from heater assembly. Refer

to Figure 43.

NOTE: Refer to appropriate wiring diagram

when rewiring heater assembly.

2. Set meter to read Ohms. Apply meter probes to

the heater assembly terminals. Meter should

read as follows: (Cold Ohms). Refer to

Figure 43.

Color

KW

Voltage/Hz.

Resistance Reading

Orange

5.35

240 V 60 Hz.

9.6 ± .31 Ohms cold

White

4.75

208 V 60 Hz.

8.2 ± .5 Ohms cold

Red

5

240 V 60 Hz.

10.4 ± .32 Ohms cold

Green

4.8

240 V 50 Hz.

10.8 ± .32 Ohms cold

Yellow

4

240 V 50 Hz.

13.0 ± .40 Ohms cold

Blue

3.1

240 V 50 Hz.

16.7 ± .50 Ohms cold

Summary of Contents for DAM 9

Page 1: ...DAM 9 SERVICE MANUAL INDUSTRIAL DRYERS PUBLICATION DATE 02 01 516514 ...

Page 2: ......

Page 127: ......

Page 128: ......