position.

4.2.

The log will be transported to the the proper location of the splitter when wood picking up

shovel back to the limited position.

The working of wood picking up shovel is controlled by packing up handle

,

wood picking

up shovel will be in the quiescent state when the handle in the natural position.

Pushing the handle inside

(

opposite of operator

),

the shovel is going up

,

the shovel will stop

when the handle in the middle position.

Pushing the handle outside,the shovel will go down automatically until to ground.

4.3.

When push the both splitting control lever to outside,the wood pushing base will go forward,

log splitter is running.

4.4. If the log is not longer enough,the wood pushing base can move little front then stop the

motor, loose the set screws of thrust ring by hex wrench, fix again after change the position of

trust ring, then can decide the reverse location of pushing base.

5

Adjustment

Adjustment

Adjustment

Adjustment of

of

of

of wood

wood

wood

wood picking

picking

picking

picking up

up

up

up shovel

shovel

shovel

shovel and

and

and

and drag

drag

drag

drag wood

wood

wood

wood

plate(figure

plate(figure

plate(figure

plate(figure 4

4

4

4 &

&

&

& figure

figure

figure

figure 5)

5)

5)

5)

5.1.

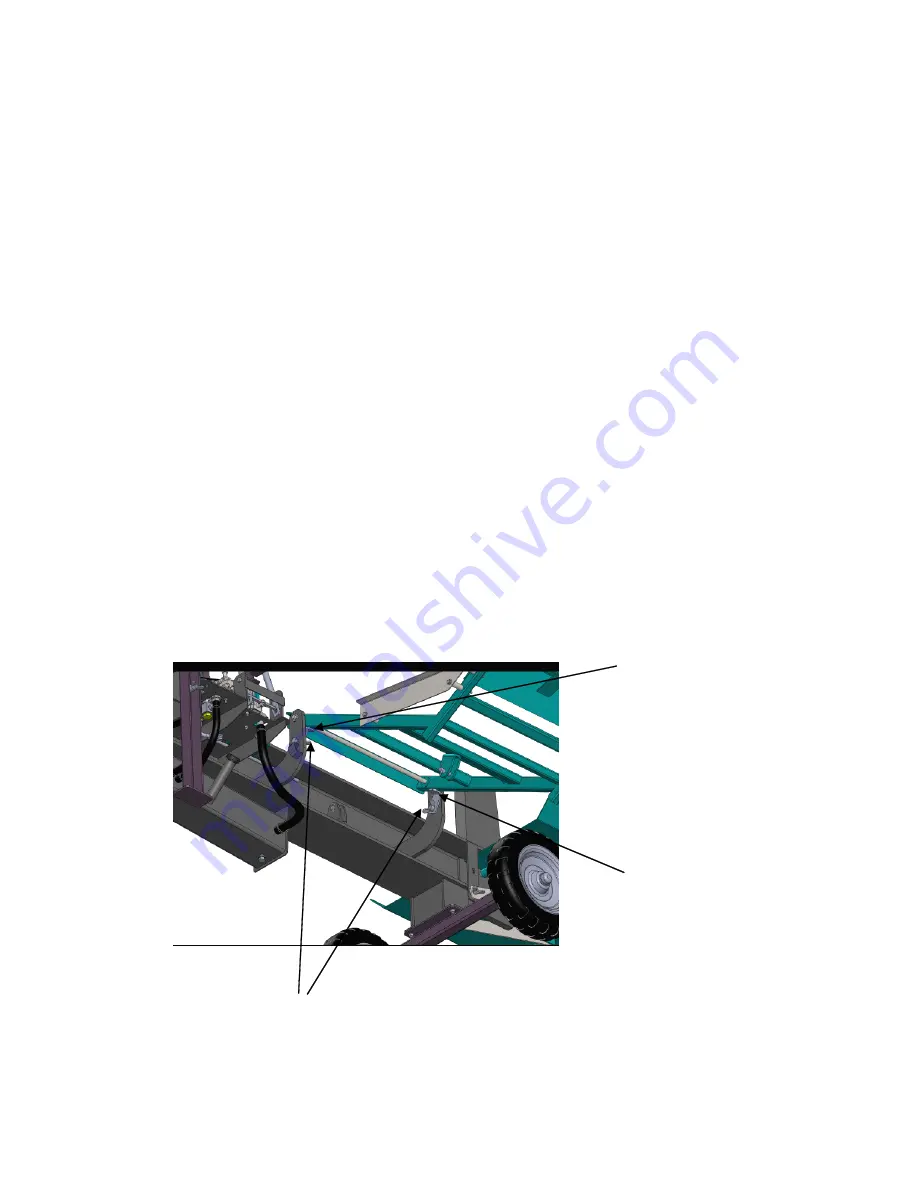

When need to move the splitter,rising picked up the shovel,use one or two valve retainer to

lock the shovel for keeping away of ground. valve retainer can locked by butterfly nuts.then shake

the handle of support wheel assembly to make the 2 jack stands leave from the ground, now you

can move the splitter.

5.2.

If want to move the log splitter for long distance, drag the plate to be rotated 90 degree,

then fix it , and move the 2 jack stand and support

wheel

assembly to the higher position and

fix as well.

Figure 4

Limit board

Limit board

Butterfly nut

8