5–30

Alignments and Adjustments

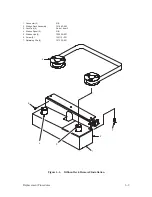

5. Perform a final position check, as follows:

a.

Install paper in the tractors and close the gates.

b. Connect an oscilloscope probe to junction of the C19 lead (7) closest

to the edge on the mechanism driver PCBA (8); this is the input to

the paper motion detector. Connect the probe’s ground clip to TP6 or

the opposite lead of C19. Set the oscilloscope between 0.1 and 1 Volt

per division as required to display the entire vertical portion of the

waveform. Set the sweep speed at about 10 mSec/division.

NOTE: Some versions of the sensor mounting clamp (4) prevent motion of

the sensor.

c.

Rotate the printer vertical position knob while observing the

oscilloscope for a maximum signal level of not less than 150 mV

peak to peak. If the amplitude is less than 150 mV, loosen the

mounting nut (2) and move the sensor toward or away from the

paper until a maximum signal level is obtained. Some high gain

sensors will provide 2 or 3 V amplitude in some cases. Tighten the

mounting nut finger tight.

d. Rotate vertical position knob while observing the scope for a

minimum signal level (with a paper hole over the sensor window –

approximately 100 mV or less).

e.

Using your fingers, rotate the sensor back and forth a few degrees on

the mounting stud to obtain an even lower signal level than in (d)

above if possible.

f.

When the lowest level is achieved, hold the sensor in position and

tighten the mounting nut.

g. Repeat (c) above to ensure that the maximum level is still 150 mV or

more. Readjust if necessary.

h. Slew the paper several times with the PAPER ADV button to check

for false paper jams. If false paper jams occur, replace the sensor and

repeat (c) through (g) above.

Summary of Contents for P9012

Page 1: ...P N 132305 001 Rev E P9012 Multifunction Line Printer...

Page 49: ...2 31 Principles of Operation Power Supply PCBAs 1 3 SHORT OPEN Figure 2 21 Power Supply PCBA...

Page 58: ...2 40 Principles of Operation...

Page 84: ...4 18 Troubleshooting...

Page 118: ...5 34 Alignments and Adjustments...

Page 203: ...6 85 Replacement Procedures This page intentionally left blank...

Page 214: ...6 96 Replacement Procedures...

Page 236: ...A 22 Power Paper Stacker Maintenance...

Page 246: ...D 2 Torque Table...

Page 254: ...Index 6...

Page 255: ......

Page 256: ...132305 001 Rev E...