A–18

Power Paper Stacker Maintenance

Test the Power Paper Stacker

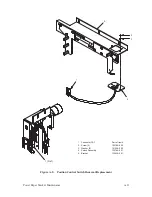

(Figure A–9)

The stacker senses the presence of paper by transmitting a beam of infrared

(invisible) light from the emitter to the light shield. When the emitter is

properly adjusted and the infrared beam is unobstructed, the BEAM LED

will be illuminated. When the beam is obstructed by paper on the rack, the

stacker will halt and the BEAM LED will go out. The paper should then be

removed and the stacker returned to the operating position (i.e., fully raised).

1. Turn on printer power and place the printer off line.

2. Open the rear printer door and locate the power stacker control panel (1).

The LED labeled BEAM (2) on the panel should be lit. If not, the

infrared light beam between the emitter (3) and the light shield (4) is

obstructed, or the emitter is misaligned. To check the alignment of the

emitter:

a.

Make sure the beam is not obstructed by anything, such as paper or

the rack.

b. Locate the emitter protruding through the access hole in the center

panel.

c.

Observe the BEAM LED on the stacker control panel. The LED

should light if the emitter is properly adjusted. Since the light beam

is infrared, it is invisible. Therefore, you must check the LED to

make sure the emitter is properly aligned.

d. If the LED is off, align the emitter by adjusting the three screws (5)

with a 7/64–inch Allen wrench.

IMPORTANT

Unscrewing the adjustment screws to the point that they disengage the

emitter causes the emitter to vibrate during printer operation.

3. Press the paper stacker toggle switch “UP.” The rack should raise until it

blocks the beam, trips the upper limit switch, or the switch is released.

Press the switch “DOWN” to lower the rack until it trips the lower limit

switch.

4. If the paper stacker does not operate as described above, verify that each

connector is properly installed and that there are no bent pins.

Summary of Contents for P9012

Page 1: ...P N 132305 001 Rev E P9012 Multifunction Line Printer...

Page 49: ...2 31 Principles of Operation Power Supply PCBAs 1 3 SHORT OPEN Figure 2 21 Power Supply PCBA...

Page 58: ...2 40 Principles of Operation...

Page 84: ...4 18 Troubleshooting...

Page 118: ...5 34 Alignments and Adjustments...

Page 203: ...6 85 Replacement Procedures This page intentionally left blank...

Page 214: ...6 96 Replacement Procedures...

Page 236: ...A 22 Power Paper Stacker Maintenance...

Page 246: ...D 2 Torque Table...

Page 254: ...Index 6...

Page 255: ......

Page 256: ...132305 001 Rev E...