14 -

PRM 60

7. ROUTINE MAINTENANCE

7.1 Initial maintenance (after 25 hours running)

Drain all oil from the gearbox, the drain plug is located on the side of the transmission, below the selector lever.

Refit drain plug. Refill with oil as stated in 4.3.

7.2 Daily checks

Check the gearbox oil level on dipstick.

Visually inspect for oil leaks and general condition of the gearbox.

7.3 Six monthly check

Check the remote control operating linkage is accurately adjusted to give maximum travel (stop to stop) in both

directions.

7.4 Annual check

All above checks.

Propeller shaft alignment inspection.

Change gearbox oil and after 500 hours or annually which ever comes first.

7.5 Cone Clutch Adjustment

The cone clutch is self-adjusting and therefore needs no adjustment. Should gear selection become difficult it is

advisable to check the installation and operaion of the control cable as discribed in 5.7. if this is correct then the cone

clutch adjustment can be carried out as decribed in 9.7.6. if problems persist after the adjustment, it will be necessary to

dissassemble the gearbox to investigate the condition of the cone clutch.

If the cone clutch shows signs of loss of coating, glazing and heat discoloration and the mating gears shows signs of

heavy groove indentations then the cone clutch and the mating gears must be replaced. If only the gears are replaced

then the adjustment of the cone clutch is not required. If the cone clutch is replaced then adjustment needs to be carried

out as described in 9.7.6.

Summary of Contents for PRM 60

Page 1: ...PRM 60 WORKSHOP MANUAL...

Page 2: ......

Page 11: ...9 PRM 60 BASIC INSTALLATION DETAILS PRM 60 Figure 4 Intallation Details...

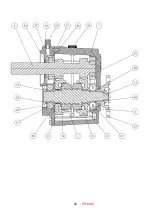

Page 23: ...21 PRM 60 13 Exploded view and Cross section Figure 5 Exploded view and cross section...

Page 24: ...22 PRM 60...

Page 25: ...23 PRM 60...

Page 26: ...24 PRM 60...

Page 28: ...26 PRM 60 NOTES...