17 -

PRM 60

9.6.2 Gearcase assembly

Remove the external locknut (25) securing idler shaft (7) into gearcase (2). Remove the ten bolts (56) securing both

gearcases (1, 2) and using a soft mallet lightly tap on the end of the input shaft (3) to separate the two gearcase (1, 2)

halves from sealant and dowels (27). Remove the front cover (1). Withdraw the idler shaft (7) the output shaft assembly

and the input shaft (3).

9.6.3 Input Shaft

Removal of the bearings (34, 38) may damage them, therefore it is good practice to replace these items if removed.

(see 9.4.3)

9.6.4 Output Shaft

Carefully remove “staked” portion of locking device so as to avoid damaging the thread and remove locknut (13) from

output shaft (14). Using a bearing puller remove the bearing (33) on the output end of the shaft (14).

Remove the following: thrust washer (8), forward output gear (10) , needle bearing (37) (carefully checking for wear),

thrust washer (9) , cone clutch (11). Using puller remove the bearing (33) on the input end of the shaft (14), thrust

washer (8), output revese gear (12), needle bearing (37) (again carefully checking for wear), and thrust washer (9).

Save shims for rebuild.

Note: Removal of ball bearings may result in damage, therefore replacement will be necessary.

9.6.5 Idler Shaft

Remove locknut (25) and supporting gear (6) on soft material i.e. wood or similar to prevent damage to gear (6), using a

soft mallet tap the shaft (7) through the gear (6) and remove needle bearing (4).

Check condition of ‘O’ ring (55) on the

idler shaft (7).

9.6.6 Selector

By hand remove selector shoe (22) and the spring (15). Remove the lever (44). Pass the selector control body (18)

through the housing (19)

and remove ‘O’ ring (20) and oil seal (21) if replacing them.

9.6.7 Front Cover

If it is required to replace the front cover (1) then it will be necessary to remove the oil seal (24). If the bearings (38, 33)

are to be re-used then care must be taken not to damage them on removal. It is recommended to fit a new oil seal (24).

Note: When re-fitting oil seal (24) set in 1.5mm from face as shown on page 18.

9.6.8 Gearcase

If it is required to replace the gearcase (2) then again if the bearings (33, 34) are to be re-used care must be taken in

their removal. Remove output seal (40), two studs (53), dipstick (28), drain and oil level plugs (26) with bonded washers

(31), oil filling plug (48) with bonded washer (54), and two dowels (27).

9.7 Re-assembly of Gearbox

(Note: coat all bearings with clean gearbox oil prior to fitting).

9.7.1 Input Shaft

Press the two bearings (38, 34) onto the input shaft (3) taking care to position correctly as illustrated. Make sure the

waved washer (39) is correctly positioned into case before fitting the input shaft (3).

9.7.2 Output Shaft (see 9.7.5 for Shimming procedure)

All of the following components are fitted in order over the output spline end of the shaft (14).

Thrust washer (9), needle bearing (37), output forward gear (10) with cone towards the scroll, thrust washer (8) and the

bearing (33) (Press on).

Fit the following components from the opposite end of the shaft (14).

The cone clutch (11), thrust washer (9), needle bearing (37), output reverse gear (12) , thrust washer (8), press on

bearing(33) (re-shim if components have been changed) (see 9.7.5). Fit lockwasher (35) and locknut (13).

CAUTION:

Remember to tighten locknuts to recommended torque.

(SEE TORQUE CHART 10.2)

Summary of Contents for PRM 60

Page 1: ...PRM 60 WORKSHOP MANUAL...

Page 2: ......

Page 11: ...9 PRM 60 BASIC INSTALLATION DETAILS PRM 60 Figure 4 Intallation Details...

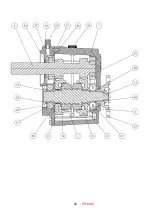

Page 23: ...21 PRM 60 13 Exploded view and Cross section Figure 5 Exploded view and cross section...

Page 24: ...22 PRM 60...

Page 25: ...23 PRM 60...

Page 26: ...24 PRM 60...

Page 28: ...26 PRM 60 NOTES...