WWW.PROCUTUSA.COM

PG /

29

Now that you have adjusted for depth, tighten the forward lock lever (over the tool arms). This lever must

be tight to minimize vibration.

For safety, it is advised at this time that you turn the motor off. Place the

chip deflector around the rotor and over the cutting tips. Grooves in the chip deflector will fit snugly over

the cutting tip screw heads when installed correctly. There are currently three types of chip deflector. The

first, the 50-703 standard version, is used in most smaller vented rotor applications. The second, the 50-

754, has double thick blocks and a lock clip to increase pressure on the rotor. The 50-754 chip deflector

works well on the thin solid rear rotors. The third, the 50-744, has thicker wire and a stronger spring for

larger vented rotors on larger cars and trucks.

Once cut depth is set, tool arms are locked down, chip deflector is secure, and draw bar tightness is double

checked, you may turn the motor back on. Press the feed engagement knob to engage the automatic feed.

Provided that you previously set the shut-off cam correctly, the lathe will shut off when the cut is com-

plete. The cut will take two to four minutes depending on the size of the rotor.

Step 4: MAKE THE CUT

(4 Minutes) CONTINUED

6.

7.

MACHINING ROTORS

Pictured above is the

50-754, which has

double thick blocks and

a lock clip to increase

pressure on solid thin

rear rotors.

Turn the dials clockwise to advance the

cutting tip depth. Each click of the dial

indicates .001”.

The chip deflectors ride over the cutting

arms as shown above. The chip deflec-

tor should be used every time.

Move the cutting head by turning the knob

shown above, clockwise for away from

the rotor, counter-clockwise for towards

the rotor.

Summary of Contents for X9D

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ......

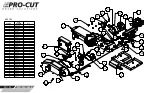

Page 10: ...1 2 3 4 5 7 8 9 11 13 12 14 6 10 PG 10 800 543 6618 Lathe Overview...

Page 41: ...WWW PROCUTUSA COM PG 41...

Page 53: ...WWW PROCUTUSA COM PG 53...

Page 59: ...WWW PROCUTUSA COM PG 59 NOTES...

Page 62: ...PG 62 800 543 6618...

Page 63: ...WWW PROCUTUSA COM PG 63...