PG /

30

800.543.6618

MACHINING ROTORS

When you are finished cutting, loosen the cutting arm lock lever, and turn the dials counter clockwise so

they will clear the larger thickness of the second rotor. Loosen the draw bar knob and remove the lathe

from the adapter. Be careful not to bump either the rotor or the wheel with the cutting head as you dis-

mount the lathe. Take special care not to bump the tips against the rotor.

Before removing the adapter from the first side, measure and record the lateral run-out on the rotor. Also

measure and record the thickness to ensure that it is above “machine to” specification. You may com-

pare to factory specifications in the Pro-Cut Brake Spec Guide provided, or other reliable certified source.

When you have finished your measurements, be sure to clear the hub, caliper bracket, and speed sensors

of any brake chips, dust or debris.

Optional: With the motor running, finish sanding with a 150 grit sand-

paper on a sanding block on each side of the rotor for 1 minute will serve to improve the surface roughness

average (Ra) by up to 25%. Excellent surface finishes provide the least amount of initial brake noise and

the best customer satisfaction.

Cleaning the rotor surface after machining to remove all dust and debris is very important in the overall

quality of the brake job. Pro-Cut recommends using liberal amounts of warm water with a mild detergent

and drying thoroughly with clean towels to be certain all loose material is removed.

Step 4: MAKE THE CUT

(4 Minutes) CONTINUED

8.

9.

10.

Summary of Contents for X9D

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ......

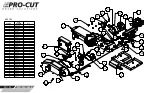

Page 10: ...1 2 3 4 5 7 8 9 11 13 12 14 6 10 PG 10 800 543 6618 Lathe Overview...

Page 41: ...WWW PROCUTUSA COM PG 41...

Page 53: ...WWW PROCUTUSA COM PG 53...

Page 59: ...WWW PROCUTUSA COM PG 59 NOTES...

Page 62: ...PG 62 800 543 6618...

Page 63: ...WWW PROCUTUSA COM PG 63...