V160K

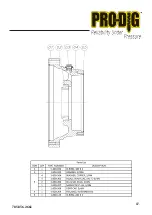

SAFETY DECAL LOCATIONS

This unit comes equipped with all safety decals in place. They are designed to help you safely

operate your unit. Read and follow all safety decals.

OPERATING PROCEDURES

Before operating always ensure that the

PRO-DIG

®

Auger Drive and auger or anchor are connected

correctly to the parent machine.

DRILLING OPERATIONS

1. To begin drilling, position the auger or anchor on the

ground in the desired location. Engage the parent ma-

chines auxiliary hydraulics to rotate the auger or anchor in

a clockwise direction.

2. Lower the parent machines arm(s) to engage the auger or

anchor into the ground. Use only enough down pressure

to assure positive penetration of the auger. Ease up on the

down pressure if the auger rotation slows down drastically

or stalls. Excessive down pressure will cause the auger to

stall frequently.

Note:

Do not continually stall the

PRO-DIG

®

Auger

Drive! Continued stalling may cause excessive heating

of the hydraulic system and possible damage to the

PRO-

DIG

®

Auger Drive.

3. As the auger or anchor digs in the ground, the parent

machines arm(s) or boom may travel through an arc. This

means the operator may need to continually reposition

the machine to ensure vertical application of the auger or

anchor.

4. When the auger has penetrated the ground about 24”

(610mm), raise the auger from the hole to clean out the

loose material.

5. Once the required hole depth is reached, allow the auger

to turn a few seconds at this depth to clean the hole.

6. Stop rotation of the auger and raise the auger out of the

hole. Swing the auger away from the newly drilled hole.

Spin the loose material off the auger.

Note:

Do not reverse the auger rotation while the auger

is still in the hole. The loose material will back fill the

hole.

7. If necessary, repeat steps 2 through 3 to obtain a cleaner

hole.

OPERATIONS TO AVOID

1. In some soil conditions or when excessive down pressure

is applied, the auger may screw itself in to the ground.

This can cause the auger to become stuck causing the

PRO-DIG

®

Auger Drive to stall. If this situation occurs,

reverse the auger rotation and slowly raise the auger from

the hole.

2. If the auger becomes lodged under rocks, tree roots, or

other large obstructions, do not attempt to raise the auger

out of the ground. See Step 1 of this section to relieve the

auger.

3. Avoid excessive side loading. This can cause damage to

both the PRO-DIG

®

Auger Drive and the auger.

4. Keep all auger teeth and pilot bits in good condition. Avoid

using damaged teeth and holders.

• Following operation, or when unhooking, stop, set

brakes, disengage power drives, shut off engine, and

remove the ignition key.

• Store the unit in and way from human activity.

• Before long term storage, wash the unit with mild

detergent and water to remove any debris and grime.

• Do not permit children to play on or around the stored

area.

• Protect the shafts and ports with a grease or rust-

inhibitor.

• Grease bearing seals.

• Check and tighten all bolts, nuts and screws. Paint is

available from your Authorized Service Dealer.

• When storing the unit for any length of time be sure

the unit is stored with clean gear oil.

WWW.PRO-DIG-USA.COM

10.

Summary of Contents for V160K

Page 15: ...785 856 2661 15 ...

Page 16: ...V160K WWW PRO DIG USA COM 16 ...

Page 17: ...785 856 2661 17 ...

Page 18: ...V160K WWW PRO DIG USA COM 18 ...

Page 19: ...785 856 2661 19 ...

Page 20: ...V160K WWW PRO DIG USA COM 20 ...

Page 21: ...785 856 2661 21 ...

Page 22: ...V160K WWW PRO DIG USA COM 22 ...

Page 23: ...785 856 2661 23 ...

Page 24: ...V160K WWW PRO DIG USA COM 24 ...

Page 25: ...NOTES 785 856 2661 25 ...

Page 26: ...PROUD MEMBER OF 1604 ROSEPORT RD ELWOOD KS 66024 785 856 2661 WWW PRO DIG USA COM ...