16

EmpyrE ElItE InstallatIOn and OpEratIOn manual

InsTallaTIon

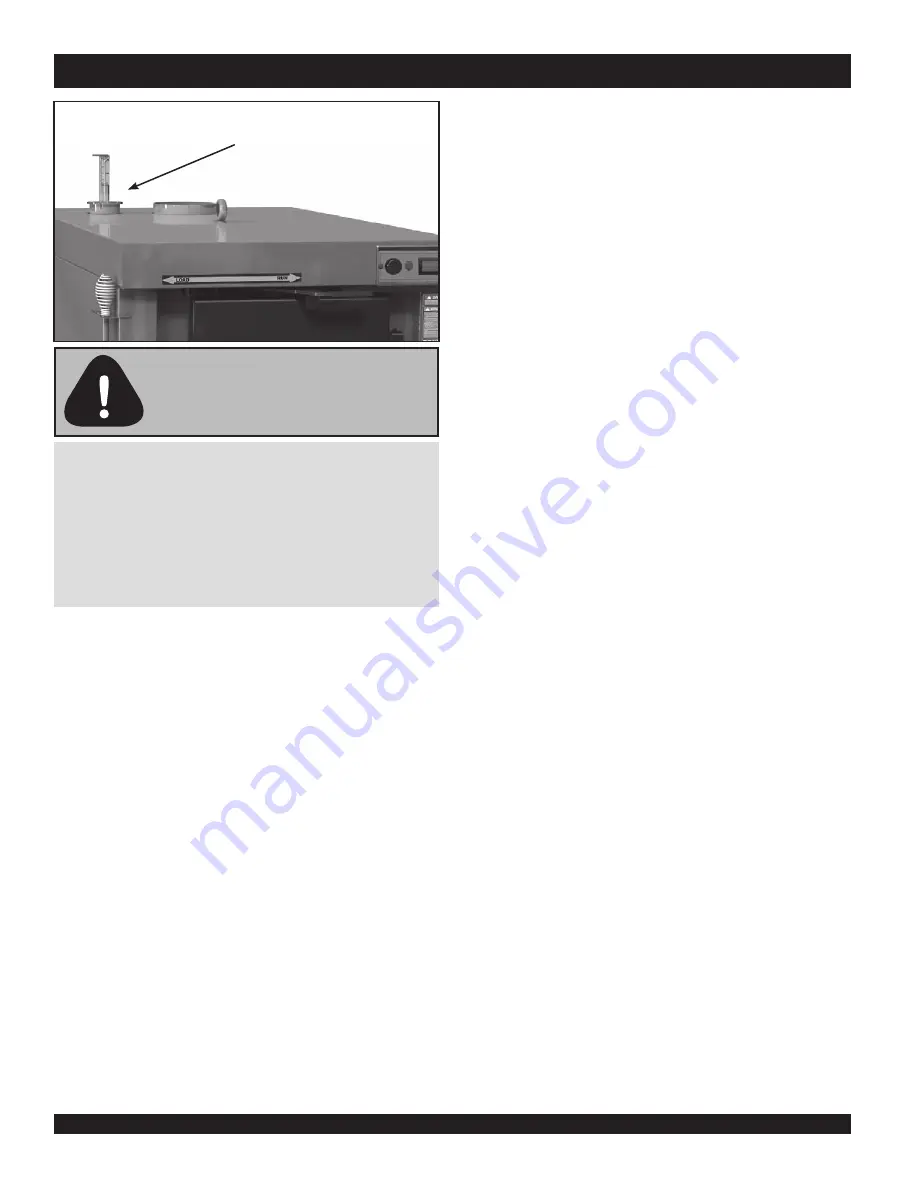

Vent opening and water

level indicator

Figure 1

KEEP THE VENT OPENING ON

TOP OF THE FURNACE CLEAR

OF ANY OBSTRUCTIONS.

IMPORTANT:

1. Use only clean, filtered water in the Empyre

Elite. Add Pro-Fab approved water treatment

to the water to prevent corrosion (available

from your Empyre dealer). For amount of

treatment to add follow instructions on the

container.

First Fill

Note: The Empyre Elite comes with an overflow port

(see page 8). a line may be connected from the port

to a drain.

1. Attach a garden hose, with two female ends, from

the water supply to the drain (see pg 8). Turn on

the water and open drain valve.

2. Check all lines and connectors for leaks.

3.

Open the SUPPLY valve (see pg 8) at the furnace

and let water run for 2 minutes and then close it.

4. Now open the RETURN valve (see pg 8) at the furnace

and let water run for 2 minutes and then close it.

5. Repeat above procedure 3 to 4 times during filling

of the furnace. Alternating between lines will ensure

that most of the air is bled from the system.

6. When the level indicator shows ADD, shut the drain

valve, shut off water and disconnect the garden

hose. Note: hot water level is higher than cold

water level.

7.

Heat furnace to operating temperature (see ‘Starting

the Fire’ below). Check water level again.

8. Add Pro-Fab approved water treatment through

vent opening, Figure 1.

9. Check water level when water temperature is

170°F (77°C) and add water until level indicator

shows full.

maintaining proper Water level

When the water level is low, the Empyre Elite may be

filled or topped up through the vent opening, Figure 1.

starting the Fire in the Hot Water Furnace

Once the Empyre Elite has been properly installed, all

connections checked thoroughly and the water system

is filled to the proper level, the unit is ready for starting

a fire.

1. Switch blower on.

2. Place some dry split kindling in the centre of the

firebox, on top of some paper, and ignite.

3. Once the kindling begins to burn, add larger pieces

of wood until the fire burns briskly. Stir the fire until a

sufficient coal bed is obtained. Do not fill the firebox

of the furnace to capacity until the water in the

furnace is hot.

DO NOT USE THE DOOR AS A LEVER TO FORCE WOOD

INTO THE FIREBOX! PIECES OF WOOD SHOULD NOT

PROTRUDE INTO THE DOOR FRAME AREA.

nOtE:

The Empyre Elite has been pressure tested at

the factory for water leaks. Some condensation may be

observed in the firebox while the furnace is coming up

to temperature after the water has become completely

cold. To avoid creosote buildup in the firebox and furnace,

burn only seasoned wood in the Empyre Elite.

maintaining proper Water temperature

Do not operate the furnace below a temperature of

165°F (74°C).

this is important in order to maintain

the warranty.

Summary of Contents for Empyre Elite 100

Page 1: ...Installation and Operation Instructions Empyre Elite Model 100 and 200...

Page 2: ......

Page 31: ......