safeTy

EmpyrE ElItE Xt InstallatIOn and OpEratIOn manual

5

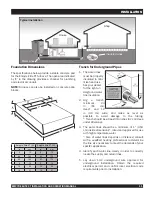

• The Empyre Elite XT furnace is designed to work in

conjunction with another heat source. We recommend

this furnace not to be used as a stand alone unit. Should

the system fail or run out of wood, a backup system must

be in place.

• The Empyre System Optimizer shipped with this furnace

must be installed in order to maintain the warranty.

• For best efficiency and cleanest burn use only seasoned

firewood. NEVER burn trash, tires, solvents, plastics,

engine oil, gasoline or other flammable liquids, rubber,

naptha, household garbage, material treated with

petroleum products (particle board, railroad ties and

pressure treated, painted, or kiln dried wood), leaves,

paper products, or cardboard.

• Start the fire with paper and small kindling.

• The Empyre Elite XT furnace is designed to operate under

atmospheric pressure only. ALWAYS keep the vent cap /

water level indicator loose over the vent opening. Do not

seal or clamp down the vent cap.

• Keep area around the furnace clean at all times to avoid

possible fire hazards. Adhere to installation clearance

and restrictions.

• The Empyre Elite XT must be installed on a level,

noncombustible floor pad, such as concrete or patio blocks.

• The Empyre Elite XT rear access cover is secured with

2 screws. Because of an electrocution hazard and hot

surfaces always keep children away. Rear access cover

must ALWAYS be in place with screws secured with wrench.

• Read the manual carefully and read all decals on the

Empyre Elite XT furnace. Should you have any questions

not answered in this manual, contact your dealer.

saFE dOOr OpEratIOn:

OutEr dOOr

Always keep outer door closed and latched during normal

operation. When door is open always secure door with door

stop rod.

lOadInG dOOr: alWays OpEn slOWly

1. Move

lEVEr

above loading door to the left, timer comes

on, wait momentarily and

slOWly

open loading door.

Timer will shut down the furnace after 5 minutes. To

reset timer, move lever to the right and then back to the

left. Lever in the right position puts the furnace into the

normal running mode, timer is then locked out.

2. After loading

ClOsE

and

latCH

door firmly and move

lEVEr

to the right.

dO nOt

operate with loading door open.

asH rEmOVal dOOr: alWays OpEn slOWly

1.

alWays

switch furnace off before opening door.

dO nOt

operate with ash removal door open.

2.

ClOsE

and

latCH

door firmly.

CautIOn!

Keep children a safe distance from the furnace.

-

dO nOt

use chemicals, gasoline, oil or any other

combustible fluid to start the fire.

-

dO nOt

store fuel or combustible materials within the

installation clearance area.

-

dO nOt

connect the unit to a chimney flue or vent that

serves a gas or other appliance.

-

dO nOt

burn trash in this furnace.

-

dO nOt

pressurize water in furnace.

-

dO nOt

damage furnace. Load wood carefully.

-

dO nOt

run furnace with water level below

add mark.

-

dO nOt

operate the furnace below a temperature of

165°F (74°C). This is important in order to maintain the

warranty.

-

dO nOt

dump ash close to any combustible

materials. Place ash in metal container and away from

combustible materials.

-

dO nOt

operate with loading or ash removal doors open.

-

dO nOt

add fuel during a power outage.

-

dO nOt

allow ash and creosote buildup. Furnace must be

kept in good condition. Follow cleaning instructions in the

Installation and Operation Instruction Manual.

-

dO nOt

use with an automatic stoker unless so certified.

-

dO nOt

modify this unit in any way. Any modification will

void the warranty.

In the event of loss of electrical power:

1. Open all flow-check and zone valves in the system.

Depending on system design, this may allow convective

circulation.

2. It is important to remember that the heating system

cannot dispose of a great deal of heat without the

circulators running. Avoid over-firing! DO NOT LOAD

LARGE AMOUNTS OF SOLID FUEL INTO THE FURNACE!

Fire the furnace cautiously until it is determined how

quickly the heat system is able to dissipate the heat

being produced by the furnace.

3. When the power has returned, reset all flow-check and zone

valves and resume normal operation of the system.

4. Check water level.

In the event of a runaway fire:

1. Ensure the firebox door is tightly closed.

2. Close all combustion air inlets on the furnace.

to cool an overheated furnace:

1. Turn all thermostats to their highest temperature setting.

safety precautions

Summary of Contents for Empyre Elite XT

Page 1: ...Installation and Operation Instructions Empyre Elite XT Model 100 and 200...

Page 2: ......

Page 31: ......