200-2705

6

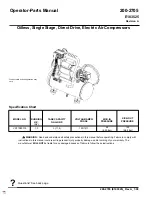

Oilless air compressors are factory lubricated for life and do not

require any oil.

The basic components of the air compressor are the electric

motor, pump, pressure switch, and tank.

The electric motor (see

A

) powers the pump. The electric

motor is equipped with an overload protector and an automatic

reset. If the motor becomes overheated, the overload protector

will shut it down to prevent damage to the motor. When the

motor sufficiently cools, it will automatically reset.

The

pump

(see

A

) compresses the air and discharges it

into the tank.

The

tank

(see

B

) stores the compressed air.

The

pressure switch

(see

C

) shuts down the motor when

the air pressure in the tank reaches the kick–out pressure. As

compressed air is used and the pressure level in the tank drops

to the kick–in pressure, the pressure switch restarts the motor

automatically, without warning, and the pump resumes

compressing air.

OVERVIEW

BASIC AIR COMPRESSOR COMPONENTS

A

B

C