3

!

PREPARATION

WARNING:

Do not lift or carry jack by the Pump Handle. Pump Handle could dislodge and jack fall, resulting

in possible injury or property damage.

Before Use

1. Before using this product, read the operator's manual completely and familiarize yourself thoroughly with the

product and its components, and recognize the hazards associated with its use.

2. Verify that the product and application are compatible. If you have questions about the use of this jack or its compatibility

with your vehicle, call Customer Support (816) 891-6390.

3. To familiarize yourself with basic operation, use the stamped end of the provided handle to engage and turn the

release valve:

a.

Clockwise

until firm resistance is felt to further turning. This is the ‘

CLOSED

’ release valve position used to

raise the saddle.

b.

Counter-clockwise

, but no more than 1/2 turn from the closed position. This is the ‘

OPEN

’ release valve position

used to lower the saddle.

NOTICE:

Use the handle provided with this jack. The provided handle will properly engage the release valve and

operate the handle sleeve. If the handle is worn, bent, operates abnormally, or will not positively engage the release

valve, discontinue use of the jack until a factory replacement handle can be acquired.

4. With saddle fully lowered and release valve closed, insert handle into handle sleeve and pump the handle. If lift

arm responds immediately, jack is ready for use. If jack does not respond, follow

Bleeding/Venting Trapped

Air

instruction below. Check oil level. Proper oil level will vary from just covering the ram cylinder to 3/16” above

it as seen from the oil filler hole. Reinstall oil plug.

5. Ensure that jack rolls freely. Raise and lower the unloaded saddle throughout the entire lifting range before putting

into service to ensure the pump operates smoothly. Replace worn or damaged parts and assemblies with genuine

factory replacement parts only.

Bleeding/Venting Trapped Air

With the release valve in the OPEN position (step 3b. above) and with saddle fully lowered, locate and remove the

cover plate, then remove the oil filler plug. Insert handle into handle sleeve and pump 6 to 8 full strokes. This will help

release pressurized air which may be trapped within the reservoir. Reinstall the oil filler plug and check operation.

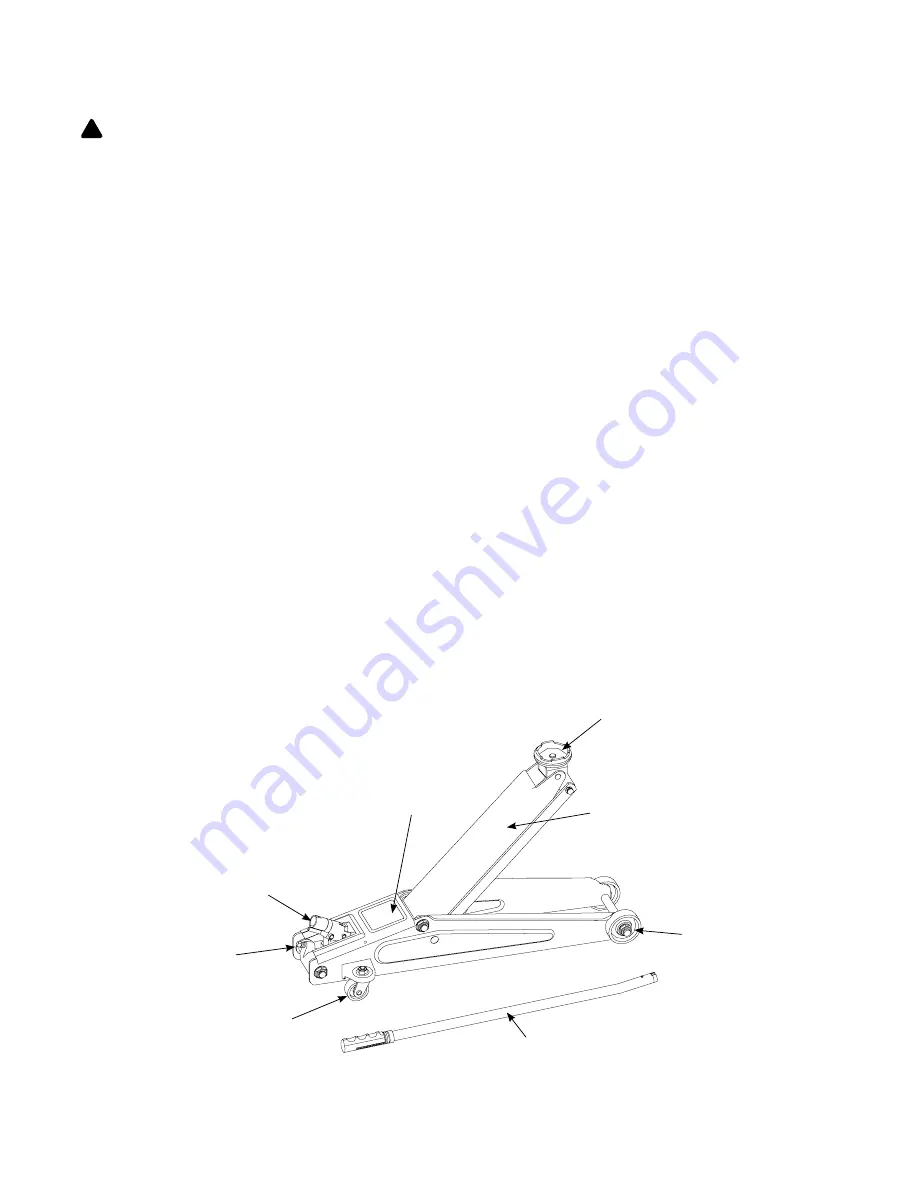

Figure 1 - Typical Floor Jack Nomenclature

Cover Plate

Oil Filler Plug

(ref. Parts illustration

for location)

Handle Sleeve

Release Valve

Rear Caster

Lift Arm

Saddle

Front Wheel

Handle

Engage release

valve with this end