TROUBLESHOOTING

(USING JACK WITHIN RATED LOAD CAPACITY)

POSSIBLE JACK PROBLEMS

POSSIBLE CAUSES AND

SOLUTIONS

(Refer to Operation and

Maintenance procedures

for detailed information)

Release valve not tightly

closed.

To close or tighten, turn

release valve clockwise.

Air is in hydraulic system.

Release air from system.

Oil level is low in jack

Add oil as required

1. Oil reservoir is over-filled

Drain out some oil.

2. Lubrication of moving

parts is necessary.

Power unit is

malfunctioning.

Replace the power unit.

Jack will

not lift

load

Jack will

lift load,

but will

not hold

Jack will

not lower

completely

Poor jack

lifting.

Pump

feels

spongy

Jack will

not lift to

full height

Handle

raises by

itself when

jack is

under load

6

LUBRICATION

• Add lubrication oil to all moving parts

every 3 months.

PREVENTING RUST

• Check Piston Rod & Pump Piston

every 3 months for any signs of rust or

corrosion. Clean as needed and wipe

with an oily cloth.

• When not using the jack, always leave

the saddle & pump piston all the way

down.

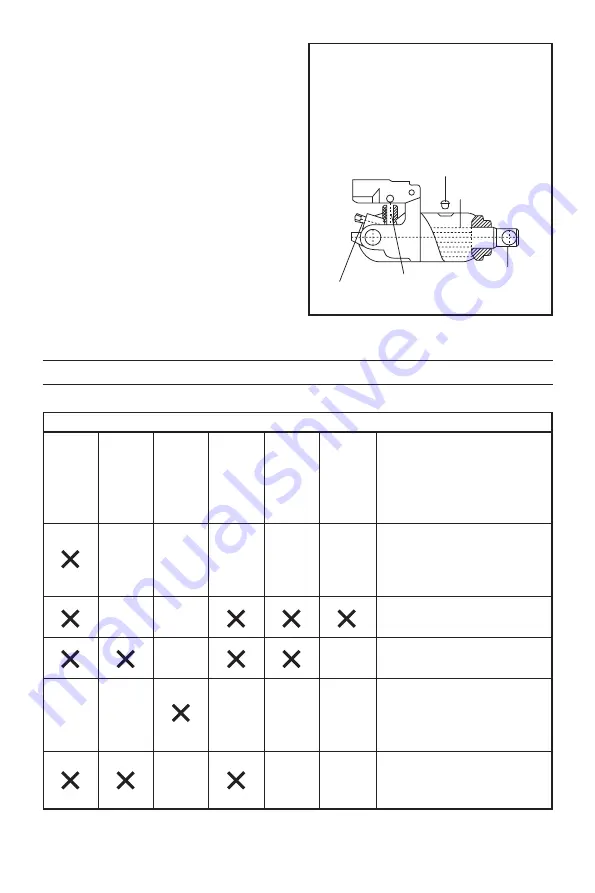

KNOW YOUR JACK

Compare these illustrations with your

jack before operation and/or oil level

maintenance to become familiar with

the location of jack components.

RELEASE

VALVE

PUMP PISTON

DOWN

PROPER OIL

LEVEL

OIL FILLER

PLUG

PISTON ROD ALL

THE WAY IN