18

Horn - Electric

The horn is used to signal, warn or alert other boats or persons on shore. The horn switch is located on the

switch panel. The horn device is located on the gunwale at the starboard side of the bow area.

Depress the horn

switch to the up or forward position to activate the horn, then release the horn switch to deactivate the horn.

Using different sequences of horn blasts indicates different and sometimes dangerous situations to you or

someone around you.

See the Safety Section in this manual for more information. Avoid any horn use without an appropriate purpose.

Additional information regarding audible warning signals should be covered in a safe boating course.

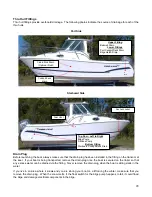

Full Instrumentation / Analog Gauges (Digital – Suzuki 300 and Verado)

All gauges are installed on the console but the configuration and specific location of your gauges will vary

depending upon the selection of the various optional engine packages. If your engine package includes the

standard analog gauges (i.e., Faria), the gauges will light up when the navigation lights are on.

Digital Gauges (Optional) - If your engine package is compatible, you may select to have the optional digital

gauges installed. With digital gauges, the gauge lights will only be illuminated when the engine is on.

Note: Digital Gauges are not available with a Suzuki engine package.

Tachometer - To ensure the tach is working properly, simply turn the ignition key on and start the engine. While

the engine is idling, the tach should be reading in the proper RPM range recommended for the engine. Your

engine manual will indicate the appropriate RPM range. When you are running at wide-open throttle, the tach

should read near the top end of the recommended RPM range.

If the RPM gauge is reading correctly and the engine throttle settings are correct, the tachometer is operating

properly. If the tachometer is not reading correctly, refer to the manual provided by the manufacturer of the gauge

that was included in your owner’s package.

Speedometer - To ensure that the speedometer is working properly, get the boat on a planing speed and check to

see if it is reading at the approximate running speed at which the boat is traveling.

Note: The speed-reading on the Speedo may vary a few mph from the actual speed that the boat

is traveling. Either a GPS or a radar gun can check the running speed.

Fuel - The fuel gauge reads the amount of fuel remaining in the tank. To check the fuel gauge, place a known

amount of fuel into the fuel fill and fill the tank. Turn the ignition key on and the fuel gauge should read the

approximate amount of fuel in the tank.

For example: If the fuel tank holds 125 gallons of fuel and you pumped 31 - 32 gallons of fuel into

the tank, the fuel gauge should read approximately ¼ of a tank. This ensures that the fuel gauge

and the fuel sender are working properly.

If the fuel gauge is not reading correctly, we recommend that you have the fuel sender checked by a qualified

professional before considering changing out the gauge. For more information, please refer to the Fuel/Oil

Systems section of this manual.

For specific information related to your gauges, refer to the materials in your owner’s package that was provided

by the gauge manufacturer.

Trim - To ensure the trim gauge/indicator is working properly, start by making sure the engine is trimmed all the

way down. Locate the trim gauge on the instrument panel and check to see if the level on the trim gauge is in the

full down position. As you trim the engine up, watch the trim gauge and ensure that it coincides with the actual

trim of the engine. When finished trimming the engine all the way up, the level on the trim gauge should read in

the full up position.

Volts - To system check the volt gauge, turn the ignition key on and turn on the engine. With the engine running,

check the reading on the volt gauge. It should be reading between 12 and 14½ volts. This reading ensures that

the charging system and the volt gauge are working properly.

Summary of Contents for 2010 23 XP

Page 2: ...ii...