11

Choosing a Charging Rate

Choose a charging rate that is appropriate for the size and type of battery being charged. Use the battery

manufacturer’s specific instructions or see the guidelines below.

Typical rates are:

Small Motorcycle/Powersport

5 Amps or less (not applicable to this charger)

Lawn Mower/Tractor

5 Amps or less (not applicable to this charger)

Deep

Cycle

15

Amps

or

less

Maintenance Free Automotive or Marine Cranking

40 Amps or less

Heavy Duty Commercial

60 Amps or less

Do not exceed the maximum charge rate recommended by the battery manufacturer or the chart above.

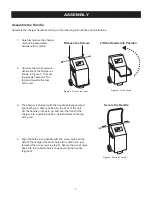

Choosing a Battery Type Setting

PRO-LOGIX Charger models utilize advanced charging technology to deliver precise charge controls, enabling them

to properly charge a wide variety of battery types.

• For Conventional and Maintenance Free Flooded (wet) Cell batteries: Choose STANDARD (STD).

• For AGM batteries: Choose AGM.

• For Spiral Wound Batteries: Choose AGM.

For batteries identified as Deep Cycle or Marine batteries, determine the construction of the battery. Is it a Wet cell,

AGM or Spiral Wound type of construction? Battery construction will determine the proper battery type selection.

Pre-Charge Battery Activation

Some modern batteries can cause charging problems if they have been deeply discharged. The plates in these

batteries can begin sulfating quickly, forming a barrier to accepting a charge. This condition will be indicated

by an extremely low (or zero) ammeter reading, indicating that the battery is not accepting current from the

charger. A deeply discharged battery such as this may take as long as 4 to 8 hours before it will accept a charge.

The Automatic Charging mode attempts to detect batteries with this condition (see Battery Repair Mode in

PREPARATION) and automatically adjusts for it.

.