8611311

180 MULTI-PROCESS MIG-ARC-TIG WELDER

V1.0

26

For technical questions call 1-800-665-8685

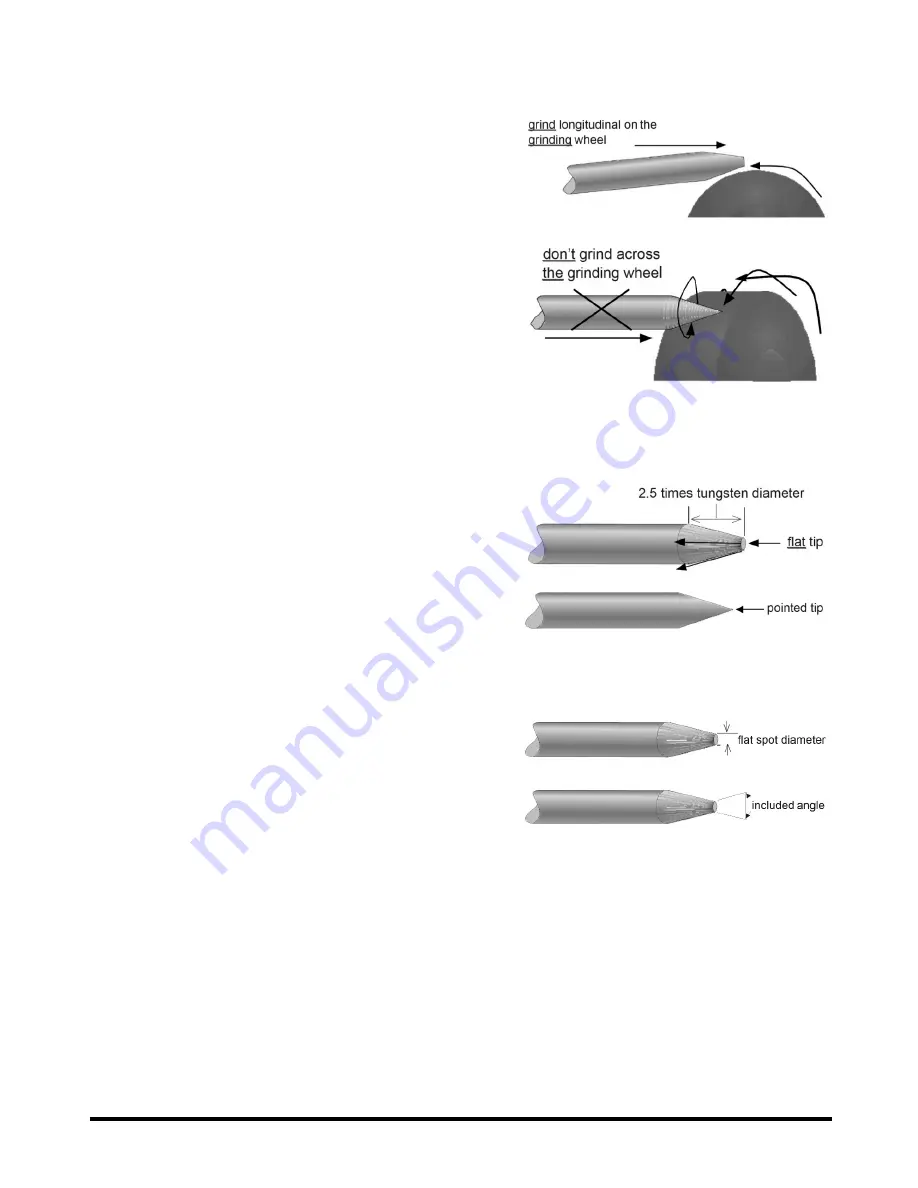

TUNGSTEN PREPARATION

Always use a diamond wheel when grinding and

cutting. While tungsten is a very hard material, the

surface of a diamond wheel is harder and this makes

for smooth grinding. Grinding without diamond

wheels, such as aluminum oxide wheels, can lead to

jagged edges, imperfections, or poor surface finishes

not visible to the eye that will contribute to weld

inconsistency and weld defects.

Always ensure to grind the tungsten in a longitudinal

direction on the grinding wheel (Fig. 57). Tungsten

electrodes are manufactured with the molecular

structure of the grain running lengthwise and thus

grinding crosswise is ‘grinding against the grain’

(Fig. 58). If electrodes are ground crosswise, the

electrons have to jump across the grinding marks and

the arc can start before the tip and wander. Grinding

longitudinally with the grain, the electrons flow steadily and easily to the end of the tungsten

tip. The arc starts straight and remains narrow, concentrated and stable.

ELECTRODE TIP/FLAT

The shape of the tungsten electrode tip is an important

process variable in precision arc welding. A good

selection of tip/flat size will balance the need for several

advantages. The bigger the flat, the more likely arc

wander will occur and the more difficult it will be to arc

start. However, increasing the flat to the maximum level

that still allows arc start and eliminates arc wander will

improve the weld penetration and increase the electrode

life (Fig. 59). Some welders still grind electrodes to a

sharp point, which makes arc starting easier. However, they risk decreased welding performance

from melting at the tip and the possibility of the point falling off into the weld pool.

ELECTRODE INCLUDED ANGLE/TAPER - DC WELDING

Tungsten electrodes for DC welding should be ground

longitudinally and concentrically with diamond wheels

to a specific included angle in conjunction with the

tip/flat preparation. Different angles produce different

arc shapes and offer different weld penetration

capabilities (Fig. 60). In general, blunter electrodes

that have a larger included angle provide the

following benefits:

•

Last Longer.

•

Have better weld penetration.

•

Have a narrower arc shape.

•

Can handle more amperage without eroding.

Sharper electrodes with smaller included angle provide:

•

Offer less arc weld.

•

Have a wider arc.

•

Have a more consistent arc.

Fig. 58

Fig. 57

Fig. 59

Fig. 60