8996928

Electric Pallet Jack

V1.0

14

For technical questions call 1-800-665-8685

use. After bleeding, if the ram still does not appear to be working

properly, do not use the ram until a qualified service technician has

repaired it.

LUBRICATION

Consult the Maintenance Checklist for lubrication points and the schedule

to perform lubrication maintenance. Use DIN 51825 standard grease at

these points.

NOTICE! NEVER use a penetrating oil to lubricate the tool.

Penetrating oil may act as a solvent that can break down the

grease and cause the tool to seize up.

TRANSPORT

1. Park the vehicle and engage the parking brake.

2. Lower the pallet jack’s forks to the lowest position.

3. Remove the battery and store separately.

4. When lifting the pallet jack with a crane, attach the hooks under the

chassis (K) upper supports (see Fig. 6).

5. Secure the pallet jack with straps. Pass a strap through each of the

holes above he load rollers and connect to either side of the vehicle.

Pass another strap around the rear of the fork so it abuts the rear

plate. Tighten all straps to prevent movement (see Fig. 7).

6. Cover the pallet jack to protect against the elements.

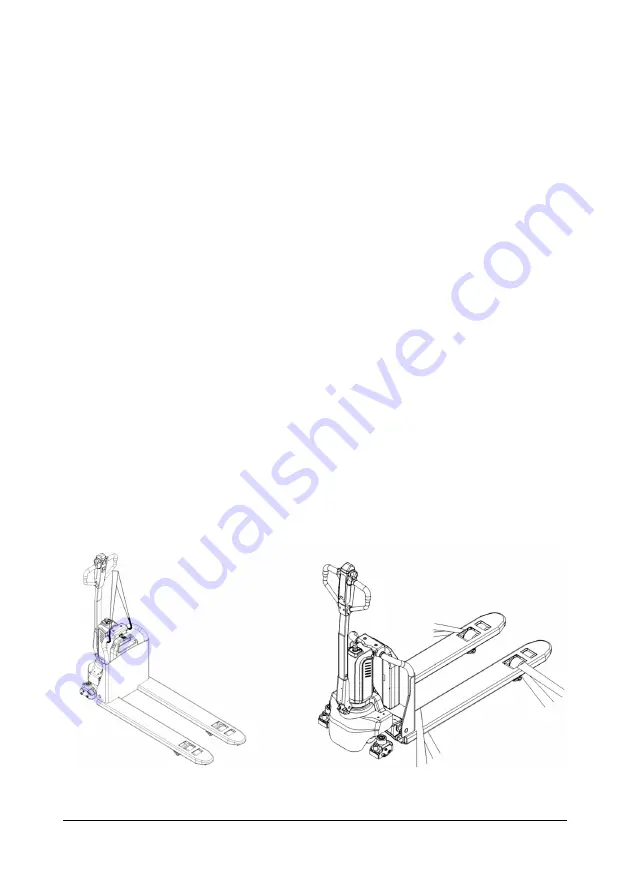

Fig. 7

Fig. 6