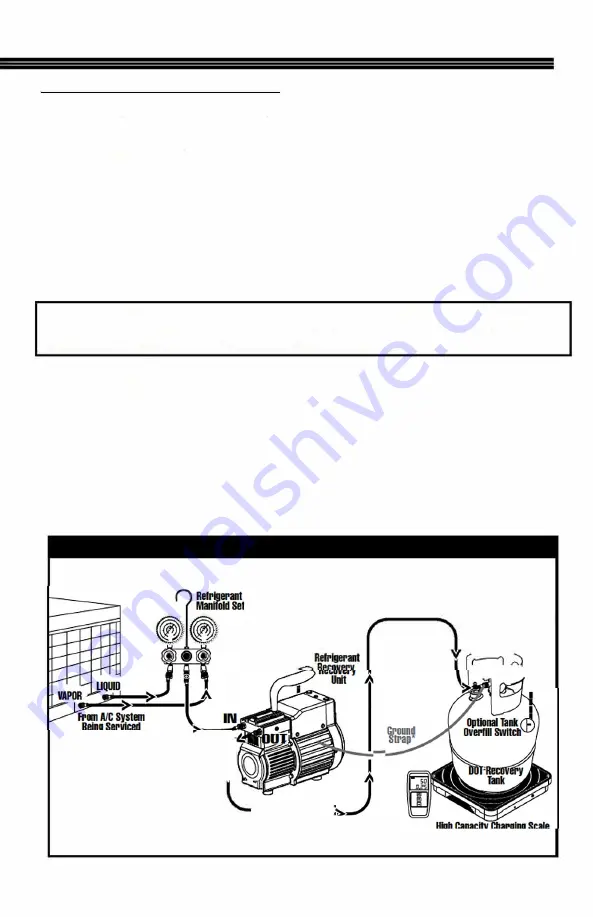

DIRECT VAPOR OR LIQUID RECOVERY

CONNECT RECOVERY UNIT (See Diagram 1)

• Use a Refrigerant Manifold (with sight glass) and two spare hoses.

• Connect Ground Strap between Recovery Unit and Recovery Tank (to prevent static electricity

build up).

1. Use a refrigerant manifold (with sight glass) and one spare hose.

2. Connect Manifold between A/C or Refrigeration Unit being serviced and Recovery Unit IN por

t

3. Connect Refrigerant Hose from Recovery unit OUT port to evacuated DOT Recovery Tank

VAPOR Valve.

4. OPEN VAPOR Valve on DOT Recovery Tank.

5. Keep Manifold Valves CLOSED at this time.

6. On Recovery Unit set Main Power Switch to ON.

7. When Recovery Unit starts,

OPEN

both HIGH & LOW Manifold Valves to start refrigerant

recovery flow.

Note: Recovery Unit is designed to directly recover large amounts of liquid refrigerant. During

Vapor Recovery, if compressor makes slugging or hammering noise, meter incoming liquid

refrigerant by closing LOW Side Manifold Valve until noise subsides.

8. Recovery Un

i

t will run continuously. When desired vacuum level is observed on

LOW

Side

Manifold Gauge, close both LOW &

HIGH

Side Manifold Valves.

CAUT ION: For Class A2, A2L and A3 recovery, Recovery Unit must be turned off when o Psig

to prevent possible ingestion of air during recovery process.

9. If Pressure on HIGH Side Manifold Gauge starts to rise, repeat steps 6-8.

10. If HIGH Side Manifold Gauge remains in a vacuum, close all tank, manifold and hose valves.

11. Remove discharge hose from Recovery Unit OUT Port. Recovery and Self-Clearing are now

complete.

Diagram 1 -

D

i

rect Vapor Or Liquid Recovery

Tolll Pll'tlln

{

Recffll'Y lllllt

V/

•

Must be bare metal to bare metci ccntact.

Olltllnal 1111111 llvel'tl sea. COi'•

(------------,

I

rtw

001 Pll't

I

I

To 1111111 vap.,

I

I

VIIVe

--,

.

�11

!>----�

5

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176