INSTALLATION

Operating Manual No: PWOM-215/250MP-001

Page 24

© 2018 Global Welding LLC

4.13

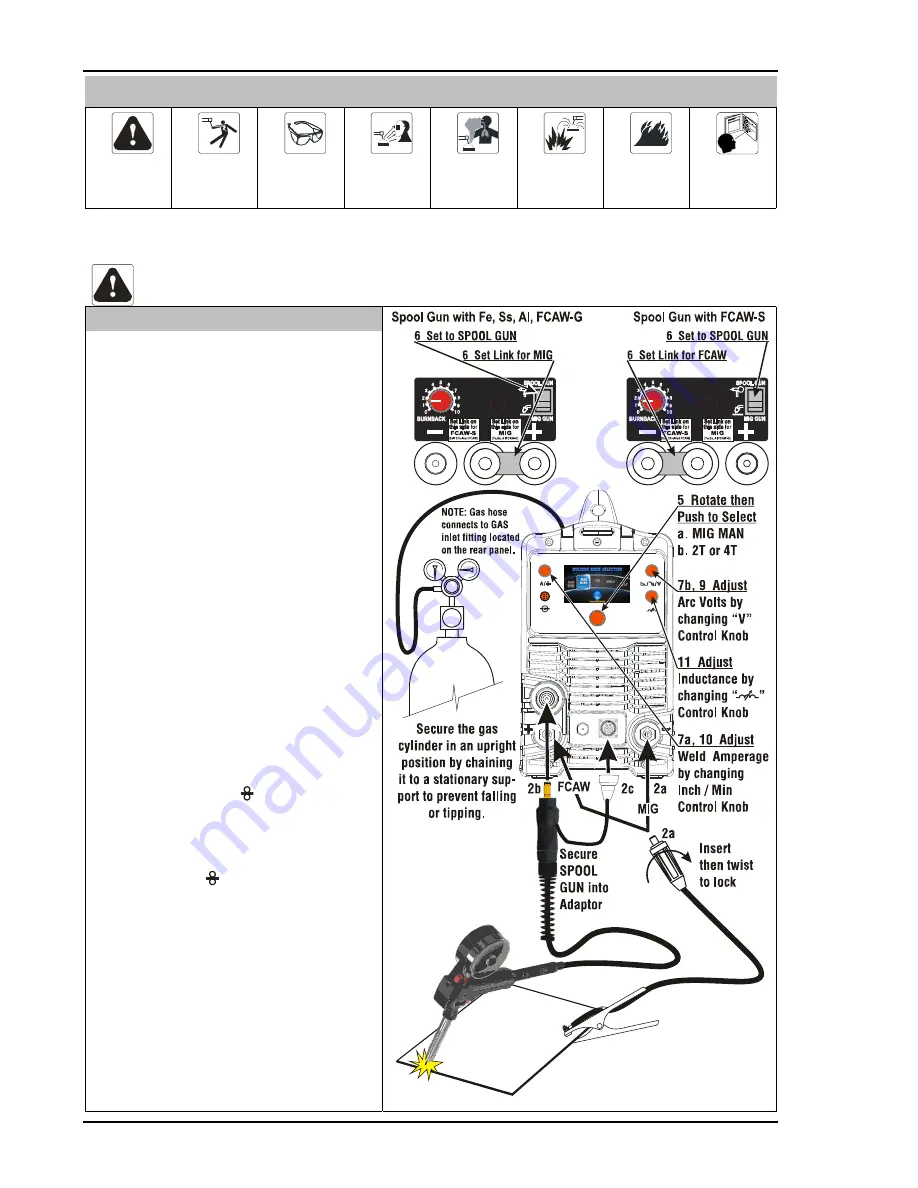

MIG MAN SPOOL GUN Setup for MIG/FCAW (GMAW)

Danger! Protect

yourself and

others

Electric shock

can kill

Flying metal or

dirt can injure

eyes

Arc rays can

burn eyes and

skin

Fumes and

gases can be

hazardous

Welding can

cause fire or

explosion

Improper instal-

lation can cause

fire

Read Operating

Manual

NOTE

13

:

Wide safety margins provided by the design allow the Power Source will withstand short term overloads without

failure. The Welding Setup Data values should be used as a guide only then fine tune one or more of the Welding Setup Data

values to suit the welding application.

Before connecting the welding cables make sure the Input Power Supply is switched off. Remove any packaging ma-

terial prior to use. Do not block the air vents at the front or rear of the Power Source.

MIG MAN SPOOL GUN Setup Sequence

Refer to SECTION 5 –

OPERATION

for explanation of controls.

1

Switch the Power Switch (located on the rear

panel) to OFF position.

2

Connect the leads as follows:

a.

Earth Clamp Lead

to the

Negative

Output Ter-

minal for

MIG

or

Positive

Output Terminal for

FCAW

b.

SPOOL Gun Lead

to the

MIG Gun Adaptor.

c.

8 Pin Plug

to 8 pin socket

d.

Gas Hose to the Gas Input on rear panel then

turn ON the shielding gas.

DO NOT over tighten the gas fittings.

e.

Fit a 4” (100mm) Welding Wire Spool into the

Spool Gun; refer to Spool Gun Operating Manual

for details.

3

Plug the Power Source into Input Supply Voltage.

4

Switch the Mains Power Supply ON & Power

Switch (located on the rear panel) ON. This will

immediately energize the Power Source.

5

Rotate Knob then PUSH to SELECT

a.

Welding Mode Selection

to MIG MAN

b.

Welding Type Selection

to 2T or 4T

6

Set Switch to SPOOL GUN & LINK to MIG or FCAW

located behind the Wirefeed Compartment Door.

7

Use Set Up Chart located on the door using Mate-

rial, Wire Type/Diameter, Shield Gas and Material

Thickness to set:

a.

Wire Speed ‘‘Inch/Min

’’

b.

Voltage ‘‘V’’.

8

Commence welding.

9

If needed, adjust the Voltage ‘‘V’’ Control Knob.

10

If needed, adjust arc amperage by changing Wire

Speed ‘‘Inch/Min

’’ to obtain the welding condi-

tion required.

11

If needed, adjust the Inductance Control Knob.

12

Leave Power Switch ON for 3 minutes to cool

down internal components after welding complet-

ed.

13

Switch the Power Switch to the OFF position.

POWER DOWN

the Power Source by switching the

machines Power Switch OFF then unplugging the

Input Power Cord from the wall socket or wall discon-

nect device. Use established Lockout/Tagout proce-

dures, refer to OSHA 29 CFR 1910.147, when discon-

necting the Welder’s Input Power Cord from the Input

Supply Voltage.