TROUBLESHOOTING and MAINTENANCE

Operating Manual No: PWOM-215/250MP-001

Page 30

© 2018 Global Welding LLC

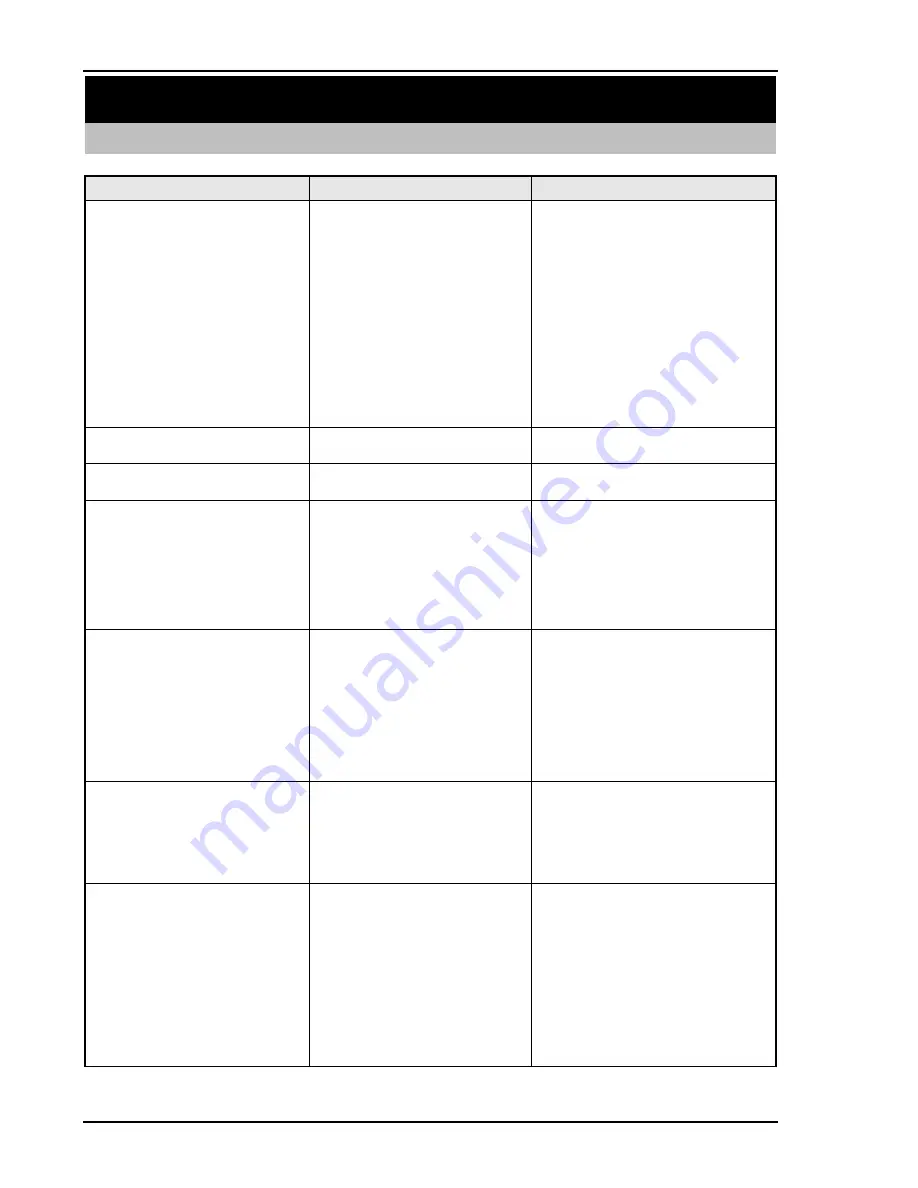

SECTION 6 – TROUBLESHOOTING and MAINTENANCE

6.1

MIG/FCAW (GMAW) Welding Troubleshooting

NOTE

20:

Weld quality is dependent on the correct consumables, proper welding technique and equipment maintenance

Description

Possible Cause

Remedy

1.

Porosity: gas pockets or holes in weld

metal.

A

Surface impurities such as oil, grease,

paint, etc.

B

Insufficient shielding gas coverage.

C

Wrong shielding gas.

D

Dirty welding wire.

E

Welding wire extends too far out of noz-

zle.

F

Incorrect distance between the MIG Gun

nozzle and the work piece.

A

Clean joint before welding.

B

Check for shielding gas flow of 15-45 CFH.

Remove spatter from gun nozzle.

Check gas hoses for leaks.

Stop air drafts near welding arc.

C

Check that you have welding grade correct

shielding gas.

D

Use clean, dry welding wire. Eliminate pickup

of oil or lubricant on welding wire from liner.

E

Be sure welding wire extends not more than

13 mm beyond nozzle.

F

Distance between MIG Gun nozzle and the

work piece (Stick-Out length) to 3/8”-1/2”.

2.

Excessive Penetration: weld metal melt-

ing through base metal.

A

Amperage and/or Voltage too high.

B

MIG Gun travel speed is too slow.

A

Reduce Wirefeed Speed or lower Voltage.

B

Increase MIG Gun travel speed.

3.

Burn Through: weld metal burns through

base metal producing holes.

A

Amperage and/or Voltage too high.

B

MIG Gun travel speed is too slow.

A

Reduce Wirefeed Speed or lower Voltage.

B

Increase MIG Gun travel speed.

4.

Lack of Penetration: no melting between

weld metal and base metal.

A

Improper joint preparation or material

too thick.

B

Improper weld technique.

C

Insufficient heat input into weld puddle.

A

Joint design must allow access to the bottom

of joint with a welding wire stick-out length of

3/8”-1/2”.

B

Requires a MIG Gun angle of 0-15°

for maxi-

mum penetration. Keep arc on leading edge of

weld puddle.

C

Set higher Wirefeed Speed and/or higher

Voltage or reduce MIG Gun travel speed.

5.

Excessive Spatter: molten metal particles

solidify onto base metal.

A

Wirefeed Speed too high.

B

Voltage too high.

C

Welding wire Stick-Out too long.

D

Work piece dirty.

E

Insufficient shielding gas at welding arc.

F

Dirty welding wire.

A

Reduce Wirefeed Speed.

B

Reduce Voltage.

C

Reduce Stick-Out length to 3/8”-1/2”.

D

Remove all grease, oil, moisture, rust, paint,

undercoating or dirt from work surface before

welding.

E

Increase shielding flow to 15-45 CFH.

F

Use clean, dry welding wire. Eliminate pickup

of oil or lubricant on welding wire from liner.

6.

Wire feeds out of MIG Gun but no shield-

ing gas flows.

A

Gas cylinder empty.

B

Gas regulator closed.

C

Faulty solenoid or electronics.

D

Restriction in MIG Gun cable.

A

Change to a full gas cylinder.

B

Open gas regulator.

C

Have an approved Service Provider repair the

connection. Refer to SECTION 7 – PRO-TEC

WARRANTY POLICY.

D

Straighten out MIG Gun cable.

7.

Drive Roll rotates but welding weld does

not feed out of the MIG Gun.

A

Insufficient Drive Roll pressure.

B

Incorrect Drive Roll size.

C

Excessive wire spool brake tension.

D

Wrong Liner or blocked Liner.

E

Welding Wire bird nest in the wire feed

system.

F

Welding wire has fused (burnt back) onto

the contact tip.

A

Increase pressure on the Drive Roll by turning

Pressure Device clockwise.

B

Fit a suit size and type of Drive Roll that suits

the welding wire.

C

Reduce wire spool brake tension by turning

the Tension Screw counterclockwise.

D

Replace the Liner to suit the Welding Wire.

E

See No. 8 Welding Wire bird nest.

F

See No. 9 Burnt Back onto the contact tip.