ARC 8 0 0

PRO

WEL D

source (standard set-up is straight polarity - Negative to con-

troller (or gun) and Positive (ground cable) to the work sur-

face).

6. Turn on the power supply and adjust the current and time

for the weld base diameter of the fastener to be welded.

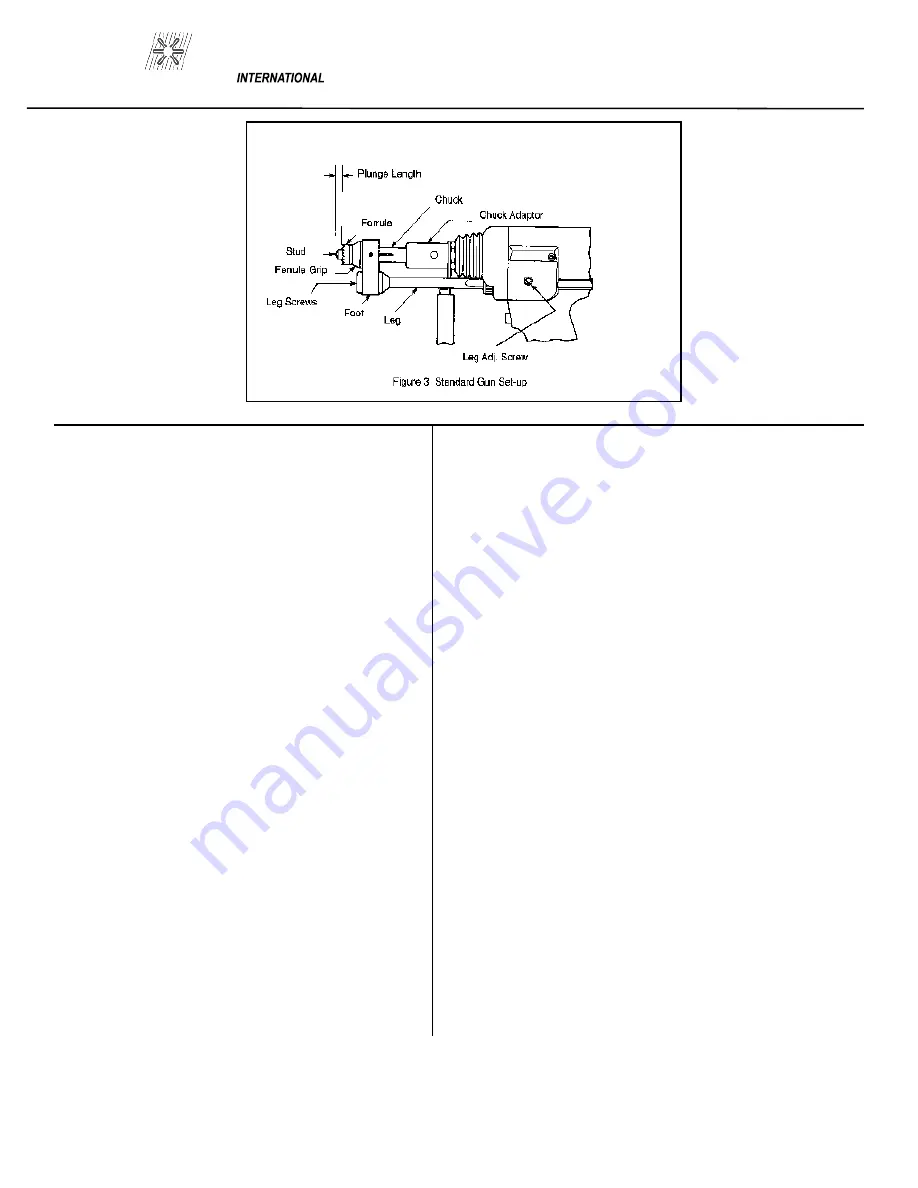

7. Place the gun, loaded with the stud and ferrule, squarely

against the grounded work surface. The main spring in the

gun will take up the “plunge length” and the ferrule will seat

against the base plate.

DO NOT MOVE THE GUN DURING THE WELD CY-

CLE

8. Pull the trigger holding the gun completely still as above.

The gun will lift the stud from the base plate and draw an

arc. The end of the stud and the adjacent material of the base

plate, will be melted by the weld arc.

The gun will then plunge the stud into the molten pool, extin-

guishing the arc, to end the controlled portion of the weld

cycle.

9. After the controlled weld cycle, allow the molten metal to

solidify briefly with the work surface to assure completion

of the cycle (about an extra second holding "still" after the

weld is usually sufficient).

10. Remove the gun from the work by lifting straight away

from the welded stud (this will assure better life to the gun's

expendable accessories). The ferrule may now be removed

by breaking it away from the welded stud to allow inspect-

tion of the weld results. After inspection of sample welds the

gun can be adjusted, as per the step in this procedure,

for optimum results.

8.2 Checking Gun Lift

To measure lift, turn the stud welding unit on and set the

timer to maximum time. (On certain units there may be a Lift

Check switch available, and in these cases this switch can be

used to check lift.) Trigger the gun in the air, or on a

non-grounded or insulated surface, to observe the lift cycle.

Measuring the distance the stud or gun mechanism

moves equals lift - usually this can be easily done by visual

observation or simple measurement against a static ref-

erence point (i.e. the ferrule properly seated in the ferrule

grip).

Recommended Lift Settings.

Stud Base Dia. Lift Setting

Less than 1/2” 1/16”

1/2” through 3/4” 3/32”

Greater than 3/4” 7/64”

When it does become necessary to adjust lift, you do so by

removing the rear cap from the gun. This will expose the

rear coil yoke assembly, the set screw and the lift adjusting

screw (Loosen the set screw to avoid damaging the threads

of the lift adjusting screw).

To increase lift: turn the lift adjusting screw out (counter

clockwise).

PAGE 4

Summary of Contents for ARC 800

Page 1: ...OPERATION MAINTENANCE MANUAL ...

Page 2: ......

Page 4: ...ARC 800 PRO WELD ...

Page 5: ...ARC 800 PRO WELD ...

Page 6: ...ARC 800 PRO WELD ...

Page 7: ...ARC 800 PRO WELD ...

Page 19: ......