ARC 1 8 5 0

PRO

WEL D

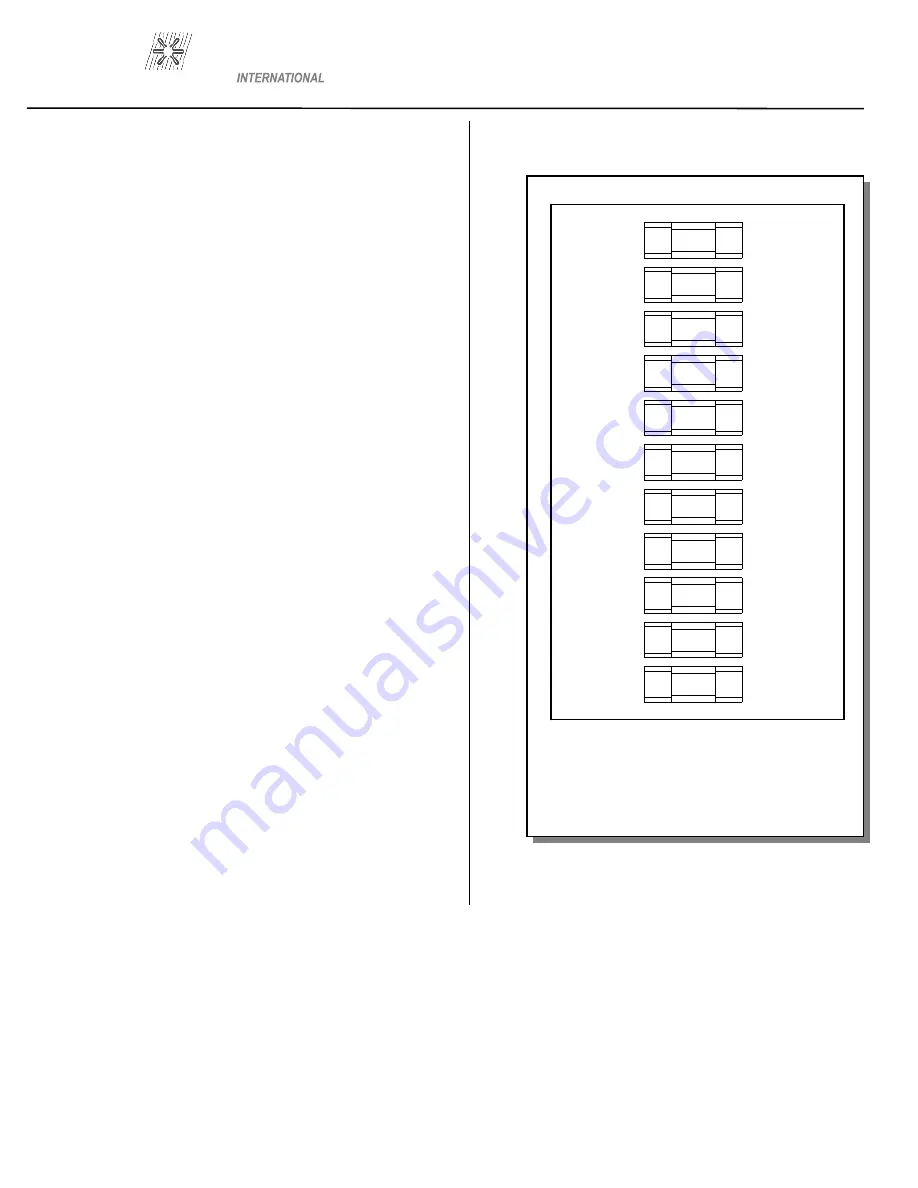

Figure 4

FUSE BLOCK

(Dual gun version shown)

F12

F11

F10

F9

F8

F7

F6

F5

F4

F3

F2

25 AMP

SLO BLO

5 AMP

CERAMIC

1 AMP

1 AMP

1 AMP

1 AMP

1 AMP

25 AMP

SLO BLO

25 AMP

SLO BLO

1 AMP

1 AMP

8.2 Checking Gun Lift

To measure lift, turn the stud welding unit on and set the timer to

maximum time. (On certain units there may be a Lift

Check switch available, and in these cases this switch can be used

to check lift.) Trigger the gun in the air, or on a

non-grounded or insulated surface, to observe the lift cycle. Meas-

uring the distance the stud or gun mechanism

moves equals lift - usually this can be easily done by visual obser-

vation or simple measurement against a static ref-

erence point (i.e. the ferrule properly seated in the ferrule grip).

Recommended Lift Settings.

Stud Base Dia. Lift Setting

Less than 1/2” 1/16”

1/2” through 3/4” 3/32”

Greater than 3/4” 7/64”

When it does become necessary to adjust lift, you do so by re-

moving the rear cap from the gun. This will expose the

rear coil yoke assembly, the set screw and the lift adjusting screw

(Loosen the set screw to avoid damaging the threads

of the lift adjusting screw).

To increase lift: turn the lift adjusting screw out (counter clock-

wise).

To decrease lift: turn the lift adjusting screw in (clockwise).

Once the lift has been set, tighten the set screw and replace the rear

cap.

PAGE 6

Summary of Contents for ARC 1850

Page 1: ...OPERATION MAINTENANCE MANUAL ...

Page 2: ......

Page 4: ...ARC 1850 PRO WELD ...

Page 5: ...ARC 1850 PRO WELD ...

Page 6: ...ARC 1850 PRO WELD ...

Page 7: ...ARC 1850 PRO WELD ...

Page 23: ......