Operating instructions SPEEDY F1

28

3.

Pull the telescopic tube carefully out of the

anti-tipping support tube and ensure that

the inlet on the telescopic tube does not

move.

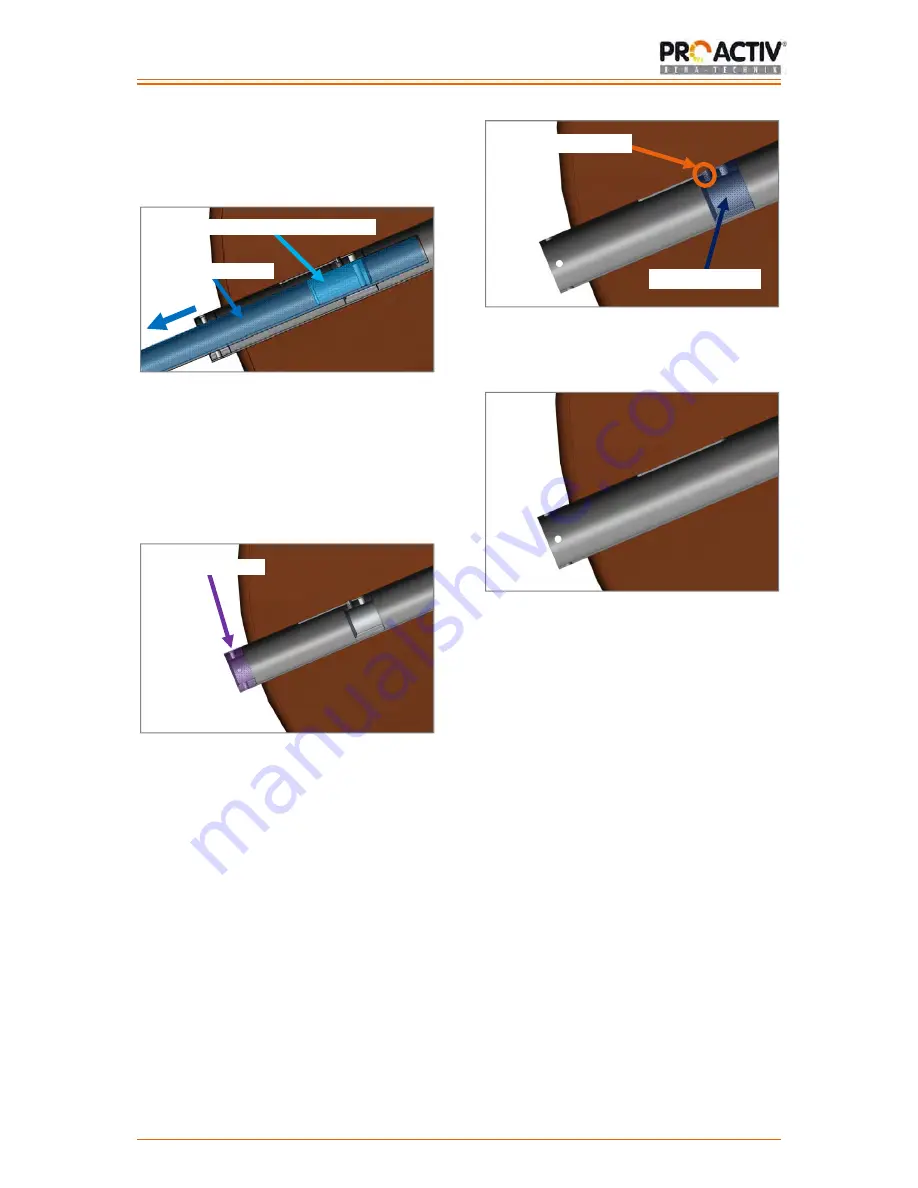

Figure 67: Pull out the telescopic tube with the inlet

from the anti-tipping support tube (sectional view)

4.

Now the screw-in inlet can be pulled out

of the anti-tipping support tube, if this has

not already come loose when the

telescopic tube was removed.

Figure 68: Telescopic tube pulled out; description of

the screw-in inlet (sectional view)

5.

Now clean the inside of the anti-tipping

support tube and the outside of the

telescopic tube (please note the

instructions in the "Cleaning and care"

chapter) until all the contamination has

been removed.

6.

Now remove the M6 grub screw and the

clamping piece. If the clamping piece

cannot easily be removed, loosen it by

gently tapping on the anti-tipping support

tube. If the clamping piece still is held

firmly in the tube, it can be pulled out

using an Allen key, for example.

Figure 69: Screw-in inlet removed; description of

clamping piece and threaded pin (sectional view)

Figure 70: All parts of the anti-tipping support

removed for cleaning (sectional view)

7.

Finally the retaining ring, the threaded pin,

the clamp lever and the screw-in inlet are

cleaned (please observe the instructions

in the "Cleaning and care" chapter) and all

sliding surfaces should be greased.

8.

The anti-tipping support is re-installed in

the reverse order after cleaning:

Insert the clamping piece back into the

anti-tipping support tube and screw in

the M6 grub screw by 1 to 2 turns.

Insert the screw-in inlet into the anti-

tipping support tube from the front.

Insert the telescopic tube into the anti-

tipping support tube and ensure that the

inlet found in there is correctly

positioned. Here, the thread on the inlet

for the clamp lever must be positioned

directly behind the hole for the clamp

lever in the telescopic tube.

Screw-in inlet

M6 grub screw

Inlet on the telescopic tube

Telescopic tube

Clamping piece