Usage instructions SPEEDY F4 and F2

53

6. Retrospective fine adjustments can be

made at any time using the infinitely ad-

justable adjustment screw on the lower

mount of the wire rope. To do this, open

the lock nuts (AF 8 mm) and unscrew the

adjustment screw. This will tension the

wire rope until the required distance be-

tween the brake pin and the drive wheel is

reached. Then tighten the lock nuts again

with a tightening torque of 4 Nm.

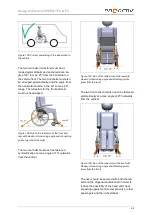

Figure 152: Fine adjustments can be made on the

brake using the adjustment screw on the lower

mount of the wire rope

25.3 Integral parking brake (SPEEDY

F2)

25.3.1 Opening and closing the brake

Figure 153: Overview of terms

Closing the brake

is carried out by pressing

the front part of the control element to the right

or left outwards until the brake element rests

against the tyre. Then press the control ele-

ment (on the front part) towards the tyre until

the control element rests against the brake

element and the brake noticeably engages.

Figure 154: Integral brake open, closing is carried

out by pressing the control element outwards

With the brake closed, the brake element is

perpendicular to the brake mount and the

brake element pushes approximately 4 mm

into the tyre (with the specified air pressure in

the tyres).

Figure 155: Integral brake closed, brake element

vertical to the brake mount

Please note that the integral brake is a

parking brake which may only be applied when

the product is at a standstill. This is not a ser-

vice brake which is suitable for reducing

speed.

Lock nut

Adjustment screw

Front part of the

control element

Brake element

Press the front part of

the control element to

the outside

•

Control element

Control element rests

against the brake element

Brake mount