9

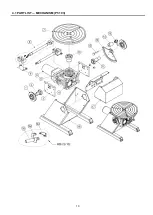

4.1 PART LIST

― MECHANISM (PT-103)

Item.

Part No.

Description

Q’ty

Remark

1

0312-0501

Shaft

2

2

5012-1150200-11

Reducer shaft

1

3

5112-1130000-10

Reducer fixing plate

2

4

0353-0332

Worm reducer

1

5

0351-0109

Gear reducer (15K)

1

A

:

0.3~4 rpm

0351-0115

Gear reducer (7.5K)

1

B

:

0.6~8 rpm

0351-0122

Gear reducer (5K)

1

C

:

0.8~12 rpm

0351-0129

Gear reducer (3.6K)

1

D

:

1.0~16 rpm

6

*

0361-1002-9

PMDC Motor w/ cable & terminals

1

7

5010-1010100-10

Faceplate

1

8

5010-2040010-20

Grounding brush w/ conducting seat

1

9

5114-12305105000-10

Grounding brush mounting plate

1

10

5114-12305104000-10

Reducer flange

1

11

5012-1150100-20

Reducer Shaft

1

12

5012-2320000-20

Tilt fixing axle

1

13

5012-2300000-20

Tilt angle plate

1

14

5012-2310000-20

Tilt fixing module

1

15

0130-0125

Tilt fixing handle

1

16

5012-1120000-20

Base column plate

1

17

6511-0110

Control box

1

CB-101 (Option)

6511-0120

Control box

1

CB-102 (Option)

18-1

*

3231-2007-9

Proximity sensor w/ connector

1

With CB-102

18-2 5010-4041000-30

Proximity sensor bracket

1

With CB-102

18-3 5010-4040000-30

Fixed sensing plate

1

With CB-102

*

Recommended spare parts

Summary of Contents for PT-103

Page 2: ......

Page 13: ...6 2 4 TIMING DIAGRAM CB 102...

Page 17: ...10 4 1 PART LIST MECHANISM PT 103...