OWNER’S MANUAL

Important

:

Read these instructions before installing, operating or servicing this product.

MODEL

:

TR

‒

3504

TURNING ROLL (Digital)

Serial Number

:

200907003 ~ Later

Revised Date: Sep. 18

th

, 2020

UNITED PROARC CORPORATION

No. 3 Gungye 10

th

Road, Pingjen Ind. Park,

Tel No

:

886 3 4696600

Pingjen City, Taoyuan 324, Taiwan

Fax No

:

886 3 4694499

http

:

//www.proarc.com.tw

:

customerservice@proarc.com.tw

RD-8447AE

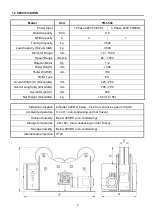

Summary of Contents for TR-3504

Page 2: ......

Page 8: ...T T TH H HI I IS S S P P PA A AG G GE E E I I IS S S B B BL L LA A AN N NK K K ...

Page 11: ...3 1 3 INSTALLATION Power Roll Idler Roll ...

Page 13: ...5 2 1 REMOTE CONTROL INSTRUCTION ...

Page 19: ...11 T T TH H HI I IS S S P P PA A AG G GE E E I I IS S S B B BL L LA A AN N NK K K ...

Page 20: ...12 5 1 CONTROL CIRCUIT 1ψ220V ...

Page 21: ...13 5 1 CONTROL CIRCUIT 3ψ380V 415V 460V ...

Page 22: ...14 5 1 CONTROL CIRCUIT REMOTE CONTROL ...

Page 23: ...15 5 2 CONTROL SYSTEM BOX 1ψ220V 3ψ380V 460V ...

Page 26: ...18 APPENDIX B CIRCUIT AC220V 1 PHASE ...

Page 27: ...19 APPENDIX B CIRCUIT AC380 415V 460V 3 PHASE ...